Sustainable. Lightweight. Efficient. World premiere of Continental’s tire concept Conti GreenConcept at IAA

- Primarily traceable, renewable, and recycled raw materials used

- Innovative lightweight design with renewable tread strip for even greater resource conservation and energy efficiency

- Purpose-engineered for tomorrow’s sensor-equipped, smart vehicles with eco-friendly drives

- Concept study underscores Continental’s commitment to fully switching its tire production over to raw materials from sustainable sources

Hanover/Munich, September 6, 2021. Continental is unveiling its innovative Conti GreenConcept tire concept at this year’s IAA MOBILITY. This conceptual study by the premium tire manufacturer leverages both current and emerging technological approaches to the engineering of sustainable tires for passenger cars, as yet another example of Continental’s wide-ranging activities in pursuit of sustainability. The goal of Continental’s integrative and sustainable concept: minimizing resource consumption across every link in the tire’s value chain. As such, the study addressed everything from the sourcing and procurement of raw materials on to the various stages of production and even on up to ways of extending the tire’s service life. Continental’s development engineers and materials experts rose to the occasion and found novel solutions to each of these three challenges. The result: a tire that consists of a particularly high percentage of traceable, renewable, and recycled materials, has an innovative, lightweight design that conserves valuable resources, and extended service life thanks to a renewable tread.

“Conti GreenConcept underscores our commitment to becoming the most progressive tire company in terms of environmental and social responsibility by the year 2030, and this ambition applies to every single link in the value chain,” commented David O’Donnell, responsible for Continental’s global tire original equipment business, adding: “The way we see it today, sustainably sourced raw materials, lightweight design and tread renewal are the key ingredients in making future generations of tires more sustainable. Our concept study exemplifies Continental’s ongoing efforts to fully transition its global tire production to sustainable materials.”

Over 50 percent sustainable raw materials used

Of all raw materials used in the making of Conti GreenConcept, more than half are either from renewable sources or recycled. For all of its tire production plants, Continental is aiming to fully transition to sustainable raw materials by no later than the year 2050. The premium tire manufacturer defines as “sustainable” all materials that originate from closed-loop cycles, have no harmful effects on people or the environment, and are responsibly sourced as well as climate-neutral across their entire supply chains.

Conti GreenConcept also consists of 35 percent renewables. Among the bio-materials used are natural rubber from dandelions, silicate from the ash of rice husks and vegetable oils and resins, all leading to a significant reduction in materials based on crude oil. In addition to natural rubber, Continental’s global tire-making plants are already making widespread use of various other materials such as recycled rubber or vegetable oils. For Continental, it has long been a top priority not only to use sustainable materials in making its tires, but also to further the cultivation and processing of such materials. For example, together with partners at its site in Anklam, Germany, Continental is conducting intensive research into the use of Russian Dandelion. The goal is to be able to grow natural rubber in the immediate vicinity of the company’s tire plants so as to both lower carbon emissions from long-distance transport and to conserve valuable resources.

Rollout of “ContiRe.Tex” technology: polyester from recycled PET bottles

Conti GreenConcept also consists of 17 percent recycled materials, namely reclaimed steel and recovered carbon black, plus – in an industry first – polyester from recycled plastic bottles for the tire’s casing. Continental is planning the gradual rollout of its ContiRe.Tex technology as of 2022, thus paving the way for the manufacture of tires using polyester yarn from recycled PET bottles. The recycling process does without the usual intermediate chemical processing steps, and the resulting polyester yarn is then made functionally capable of handling the high mechanical forces to which tires are subjected. As a part of the so-called upcycling process, used PET bottles get a new life as polyester high-performance material. Conventional passenger car tires consist of roughly 400 grams of polyester yarn each. In manufacturing a set of four tires, a total of over 60 recycled PET (polyethylene terephthalate) bottles can be reused. The use of recycled polyester marks another major step by Continental on the road to circular manufacturing for all of its tire products.

Another part of the Conti GreenConcept sustainability equation is the special mix of materials made possible by COKOON – a technology for the eco-friendly bonding of textile reinforcements with rubber compounds as developed by Continental in partnership with Kordsa. In the spirit of open-source collaboration, the two partners have been making this technology available to all tire industry players on a free-of-charge basis ever since 2019.

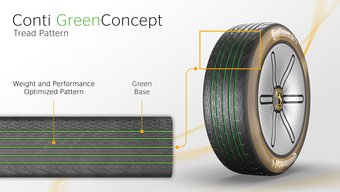

Smart vehicle concept based on resource-saving lightweight design

Besides its high percentage of renewable and recycled materials, Conti GreenConcept also raises the bar in terms of innovative lightweight technology. The tire weighs just 7.5 kilograms, making it up to 40 percent lighter than conventional tires. This weight reduction was made possible by an optimized tread pattern, a special sidewall and a new casing design with a weight-optimized core. All in all, the design choices made lead to significantly lower resource consumption and more sustainable driving.

Thanks to its lightweight design, Conti GreenConcept is particularly destined for use in next-gen smart vehicles equipped with sensors and resource-saving drives. By predictively monitoring their surroundings, the sensors in such vehicles give drivers the input they need for anticipatory driving, which in turn makes it feasible to use increasingly lightweight and resource-friendly tires.

Even lower rolling resistance thanks to materials optimization

Conti GreenConcept’s specially designed tread offers a greater margin of safety than conventional tires with the same tread depth. The materials used in the tread were also optimized, thus further reducing the tire’s weight and, in turn, lowering rolling resistance. In-house measurements reveal that Conti GreenConcept’s rolling resistance is to about 25 percent lower than class “A” – i.e. the best possible rating – under the EU Tire Label system. Low rolling resistance means lowers energy consumption, thus leading to a measurable improvement in terms of environmental impact. In the case of internal combustion vehicles, this means greater mileage and lower carbon emissions; for electrical vehicles, it results in extended range. Continental’s calculations – which have been validated by leading vehicle manufacturers – show that a 25 percent reduction in rolling resistance can lead to up to six percent greater range for electric vehicles.

Special tread strip capable of multiple renewals

The natural rubber used for the Conti GreenConcept tread compound is 100 percent Taraxagum natural rubber. As a special capability, the tire concept can be retreaded multiple times, with a minimal investment in terms of both time and materials. The green-colored tread baseline marks the transition from tread to casing. Undamaged casings can be reused several times. In this way, the valuable raw materials that are built into it can be reused. If a tread is renewed three times, for example, this halves the amount of material used for a casing as seen in terms of its total mileage. “Conti GreenConcept delivers maximum performance in terms of both flexibility and sustainability, enabling modern mobility to truly hit the streets,” commented O’Donnell.

Moreover, a latest-generation Continental sensor inside the tire makes predictive driving possible by means of continuous monitoring of temperature, pressure and tread depth. This gives drivers added input so they can make well-informed choices, thus promoting resource-friendly driving.

Continental also supplying sustainable tires for Volkswagen’s ID. LIFE concept car

In addition to the GreenConcept tire Continental is exhibiting at its own booth at IAA MOBILITY 2021, the ID. LIFE on display by Volkswagen sports yet another Continental concept. The eco-friendly tire engineering technologies used in making the tire for Volkswagen are ready to make their way into series production in the near future. Engineered on the basis of Continental’s standard EcoContact 6 tire, the concept tire scores with very low rolling resistance (EU label “A”), leading to extend range for the ID. LIFE. Thanks to the targeted use of renewable and recycled materials comprising 37 percent of its overall materials, the concept tire makes a significant contribution to resource conservation across the entire value chain. The responsible sourcing of raw materials helps to minimize environmental impact and potential human rights infringements.

The sidewalls of EcoContact 6 tires bear the slogan “Responsibly Sourced Rubber” as a way of emphasizing Continental’s wide-ranging efforts to ensure the transparent and traceable sourcing of natural rubber. Among other renewable raw materials used are silicate from the ash of rice husks, vegetable oil and vegetable resins. Recycled rubber and the eco-friendly COKOON bonding system for textile reinforcement recently launched for Continental’s series production are also part of the picture.

Conti GreenConcept and the concept tire supplied to Volkswagen for its ID. LIFE concept car serve to underscore Continental’s ambitious goal of becoming the most progressive tire company with regard to ecological and social responsibility by the year 2030. As an initial step in this direction, the company’s zero-emission mobility business is on track to becoming completely carbon-neutral as of 2022. This is an important milestone on the road to becoming fully carbon neutral, and will also help Continental’s customers to meet their own decarbonization targets. By 2050 at the latest, Continental intends to be manufacturing its tire products using 100 percent sustainably produced materials, and thus achieving full climate neutrality throughout all of its supply chains.