High-performance Computers on the Move

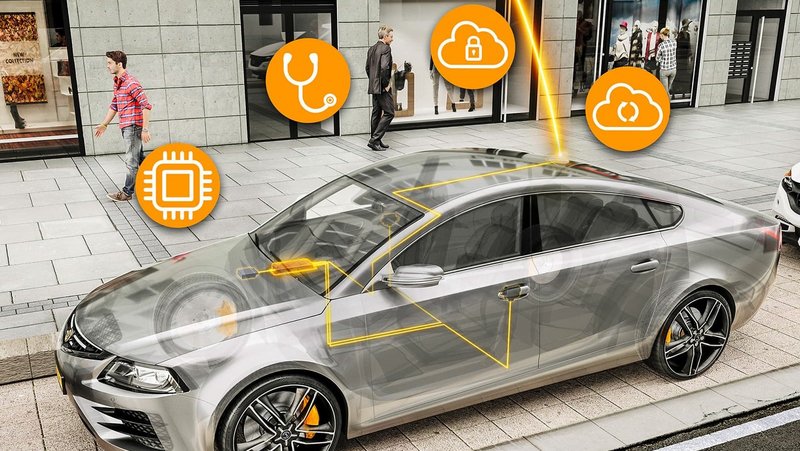

More than just a car: the vehicles of tomorrow are computers on the move, highly connected and extremely powerful. Whether it’s autonomous driving, automatic over-the-air (wireless) updates or new entertainment options, all these need on-board servers that guarantee massive computing power, high data transmission, and data security. Continental makes all this possible.

High-performance Computers on the Move

The future belongs to electric vehicles and self-driving cars. But without full connectivity and extremely high-performance computers, that future won’t get far. This also means that many of the electronic components previously cluttering up cars are no longer necessary, having long since reached their limits. In the future, modern high-performance servers will take the wheel. Continental is at the forefront of development in this area. With the ICAS1, the technology company set a milestone in production readiness – while also establishing new working methods.

Small box, big impact

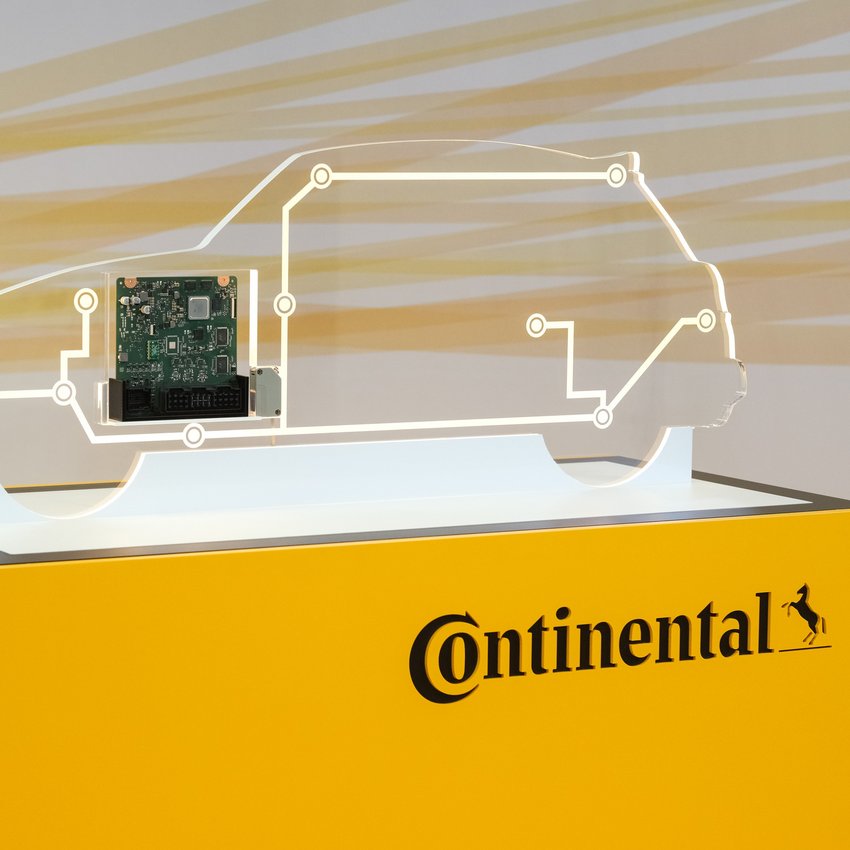

In the form of a small silver box about the size of an average paperback, the future of driving might look a little unimpressive. But inside is something truly special: a high-performance computer that will take over the central functions of millions of electric cars in the future, putting an end to the tangled clutter of electronics seen in today’s vehicles.

For the automotive industry, this small box represents a technological quantum leap: one that is barely visible on the outside, but is no less revolutionary for that. In the future, no electric car will work without it. Continental is one of the key driving forces behind this development. The company was the first supplier to bring high-performance servers for vehicles into volume production with the in-car application server, or ICAS1 for short. It is found in the new ID. range of electric vehicles manufactured by Volkswagen, Europe’s largest carmaker, and thus also on board the ID.3, which will be released from September 2020. By 2022, more than 2.5 million Continental servers will be installed on VW vehicles.

High time to clear out the clutter

Continental’s new server brings a long-awaited innovation: the myriad electronic functions in the automotive industry are finally all in one place. Over the years, car manufacturers have been constantly innovating new electronic features for their customers, and each of them comes with their own control unit and software. In today’s cars, we can find between 70 to 100 electronic control units, most of them from different manufacturers. This results in a complexity that has become almost unmanageable: not only does it demand massive computing and transmission capacities, but also makes the error-free interaction of all these functions a complicated proposition. The truly decisive factor for the changeover to a new electronic architecture is full connectivity for vehicles. In the vehicle of the future, it should be normal to keep software up-to-date and implement new functions using a smartphone or another device via over-the-air (wireless) updates. The more software functions are based on individual electronic control units, the more complex the software landscape becomes. Updates can only be made with a disproportionately large amount of effort.

Only decluttering can remedy this situation. The idea is that a mere few high-performance servers control the electric drive and functionality of the modern vehicle: hardware and software are therefore separated from each other. This means, however, that the IT infrastructure of the car must be fundamentally reassembled. Modern servers like the ICAS1 are doing exactly this by organizing the previous patchwork of modules. In the future, depending on the ID. vehicle model and its features, two or three servers will provide the computing power for the entire vehicle.

ICAS1 – a real game changer

Continental’s high-performance server promises not only a tangible reduction of complexity in the vehicle’s interior, but also a whole range of related advantages: vehicle manufacturers can, for example, reduce costs. As a result of the reduction and reorganization of the electronic control units, much of the 1.5 kilometers of copper wire installed in today’s cars can be saved. This significantly reduces the amount of materials required. In some cars, the wiring harnesses can weigh as much as an additional passenger. Avoiding this is a real advantage, especially for electric cars, where low weight is of particular importance.

First and foremost, it is the separation of software and hardware that make servers such as the ICAS1 a game changer. This enables the logic of the vehicle functions, previously handled by the electronic control units, to be transferred to the central computers. These can include electric window lift systems, headlight and tail light control, the digital measurement of tire pressure, or keyless access to the vehicle. In the future, these and other functions will be taken over by the hypervisor, as the underlying operating system developed by Continental’s subsidiary Elektrobit is known.

This means that the software can also be easily kept up to date via a wireless internet connection. As a result, ongoing vehicle diagnostics or regular updates will become the new standard. In turn, this lowers the costs of recalls and drastically reduces the need for service campaigns. In addition, the vehicles remain up to date and manufacturers can correct problems or upgrade functions later. And this is opening up a market for completely new functions and business models to third-party providers – much like smartphones have created a market for apps.

A new dimension for electric cars

It is primarily electric vehicles that depend on this new level of connectivity and digital functions. Essential services such as range-optimized route planning, finding free charging spots, or digital billing after charging are all based on a solid IT infrastructure in the car.

What’s more, “the electric car never sleeps,” says Oliver Kasch. He leads one of several teams at Continental who are developing the high-performance ICAS1 server for Volkswagen’s ID.3. According to Kasch, if you turn off the ignition of a normal car with a combustion engine, it switches off more or less completely. “But when you park an electric car, it comes to life and does its own thing. It charges its batteries, performs diagnostics, uploads data, and updates its software.” All these over-the-air (wireless) functions require the high-performance computing and transmission capacity that the ICAS1 offers.

And the server is not even close to its performance limit. The 7-core processor takes over approximately 70 external functions in the ID.3, but can do much more. “The computing power can be increased by a factor of 20 and the network speed even more,” says Kasch. Volkswagen has deliberately decided to install the high-performance ICAS1 server to set up its cars for any functions, applications and services that may be added later.

Safety first – now more than ever

The myriad applications handled by the server also require special attention in terms of the security of vehicle electronics and data. ICAS1 is a step forward in cybersecurity, since the incoming and outgoing communication is controlled at the central level via the server. This avoids the need for the countless communication interfaces of the multitude of electronic control units, which can always be a gateway for security risks.

Safety when driving is crucial. If, for example, an app on a smartphone freezes the screen, it is simply annoying. However, if an app messes up the brake lights of a car, it can quickly become dangerous. For this reason, every app must be kept separate from the safety-relevant areas of the vehicle. This is also guaranteed by the hypervisor, as the ICAS1 operating system is known.

Development was a massive undertaking

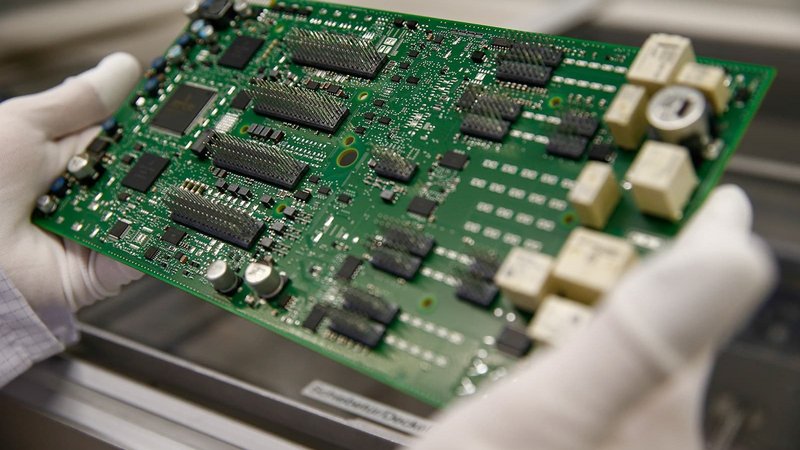

The fact that the new server handles the immense range of functions and the associated safety requirements without issues is the result of an extraordinary feat at Continental: approximately 600 developers spent almost two million hours programming the software used by ICAS1. “I’ve never seen anything quite like this before,” says Kasch, “not least because the entire product had to be developed from scratch.” And all of it in just the two and a half years which Continental had time for – not much in comparison with other product development processes of this scale.

A crucial challenge was that the new vehicle server not only had to securely integrate software for countless control functions, but also software from many different suppliers. However, with so many different functions and software products, every change and every new solution to a problem can lead to ripple effects and new problems. Project Manager Oliver Kasch says: “It is in the nature of a central server like this that everything is connected to everything else.”

Breakthrough thanks to Agile methodology

Although not from right from the start, Continental found new ways of working together in a new approach: a little more than halfway through the project, it was decided to reshape the entire workflow and rely on the Scaled Agile Framework, a method for agile practices in major development processes. Even though such a change in the middle of a project is far from ideal, Kasch believes it was decisive in its success: “It made perfect sense and helped us all turn things around in the end,” he says.

After all, the agile workflow made it possible to control the complex project sensibly and ensure important communication between developers, testers and the customer took place. Like most agile methods, conventional “silo thinking,” i.e. working in hierarchical structures organized into departments, was abandoned. Instead, they formed agile teams which bundled together all the resources and skills needed to solve a specific task. In this way, the project was broken down into manageable sub-tasks and thus handled quickly and efficiently. 42 teams working together developed ICAS1.

High-performance on-board computers are manufactured at Continental’s electronics production facility.

And something else stands out: close cooperation not only with the customer, but also at the customer’s site. In fact, around 35 Continental employees were permanently stationed at the Volkswagen offices in Wolfsburg and worked and tested side by side with their Volkswagen colleagues literally every day.

The results were pretty impressive. With ICAS1, Continental has set the course for the future – not only for the automotive industry, but also for the Continental Group. CEO Dr. Elmar Degenhart: “This collaboration has shown us the way forward. After all, it shows how we are successfully shaping the future of mobility together during a time of complex transformations.” What the company has learned and achieved in the development of ICAS1 is setting the standard for future projects and working methods. Moreover, in recent months, further contracts for high-performance computers with a total volume of more than €4 billion have been won. The successor platform ICAS1.x is already in the works.