Continental makes surfaces for the automotive, construction and furniture industries sustainable

- Innovations made of fully recycled material, with bio-based raw materials or coffee grounds

- Surface materials combine environmental and climate protection with functionality and design

- AMBIENC3 concept vehicle and Tiny House ContiHome as an example of concentrated surface expertise

Continental is focusing on sustainable surface solutions that combine design and functionality with sustainability: products with a recycled component of 100 percent in the PET polymer or from predominantly bio-based raw materials, with coffee grounds as the starting material or recyclable several times in a closed cycle. In the interiors of cars and commercial vehicles, these applications contribute to more sustainable mobility. As surfaces for indoors and outdoors or on furniture, they make buildings more climate-friendly.

Combination of recycling and bio-based raw materials conserves resources

In the automotive business, Continental has already presented two solutions at the IAA Transportation 2022, Xpreshn and Acella, which can be manufactured with biobased raw materials or from recycled materials in a resource-saving manner. Xpreshn lines the doors and instrument panels of commercial vehicles and, as a recyclable mono-material, can be completely returned to the circular economy. For the artificial leather Acella – proven in the market for more than 125 years – recycled materials and bio-based raw materials are combined today. For example, rPET technology is used, in which yarns are obtained from recycled plastic bottles and used for the backing material. Acella gives vehicles from many manufacturers a distinctive design, for example on seat covers, headrests, instrument panels, door and side panels or the centre console.

The three pillars of sustainable product design

Benova Eco Protect is sustainable in the literal sense of the word, i.e. robust and durable. The German Innovation Award-winning material is heat and UV resistant, lightweight and completely free of materials of animal origin, plasticisers, solvents or other critical ingredients. With its low Product Carbon Footprint (PCF), it contributes positively to a vehicle's eco-balance. "Our sustainable product design is based on three pillars: carbon neutrality, circular economy and unique product features. We enable our customers individual surface solutions that are up to 100 percent carbon neutral," says Dr Gabriele Wittmann, Head of Global Research in Continental's Surface Solutions Business Area.

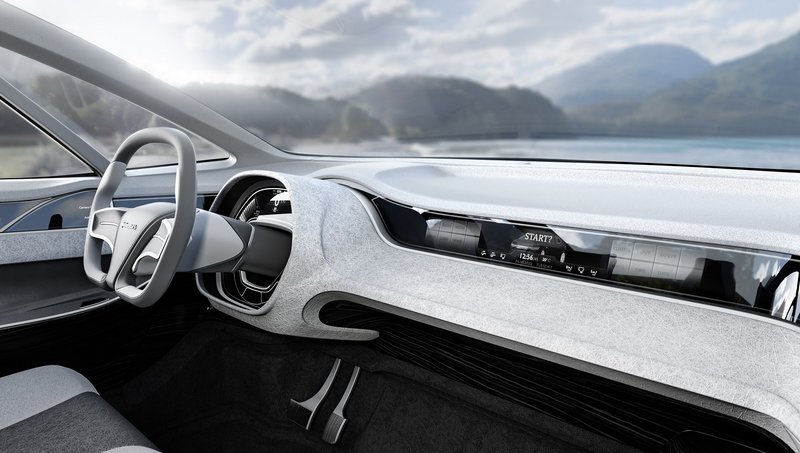

In the AMBIENC3 concept car, these surface solutions melt into a 3rd Space for mobility, work and life. The vehicle interior is no longer merely functional, but offers comfort, smart functions and high-quality designs.

Coffee grounds become breathable upholstery fabric

Continental is also continuously expanding its portfolio of sustainable solutions for the furniture and construction industries. The design laminate skai rPET PureLux consists of 100 percent recycled material in the PET polymer. It combines a soft-touch feel with high scratch resistance and an anti-fingerprint effect. The surface technology staynu, which is the basis for this, enables a long service life and thus conserves resources: it makes materials equally resistant to dirt and mechanical or chemical stress.

In the skai VyP Coffee imitation leather, the technology company uses coffee grounds as a raw material for breathable upholstery fabrics. Another variant of the artificial leather family is skai Evida, which consists of 80 percent renewable materials.

At Continental's Weissbach site, artificial leather and furniture foils are produced under the highest ecological and social standards. All ingredients are REACH-compliant, and the finishing varnishes are solvent-free.

Plastic window profiles in a closed cycle

As a premium partner of Rewindo, the leading German recycling network for discarded plastic window profiles, Continental is also taking on a pioneering role. "Window profiles coated with our films can be recycled without further treatment," explains Rainer Irouschek, Head of Exterior at Continental Surface Solutions. That is why coated plastic windows are the first choice when it comes to durability and sustainability. The PVC used can be recycled up to seven times. Rewindo's network of partner companies enables a closed cycle from the removal of old windows to the production of high-quality PVC granulate and the manufacture of new frame profiles.

ContiHome with new design concept

The mobile Tinyhouse ContiHome shows sustainable interior and exterior materials from Continental embedded in an innovative living concept. It is fully equipped with the company's innovative surface solutions and follows the in-house design concept "Indoor Garden": This is inspired by nature and makes the core theme of sustainability visible and experiencable.

Back to overview "Experience sustainable material competence"