Autonomous Driving over Long Distances: How Self-Driving Trucks Will Revolutionize Logistics

What sounded like science fiction a few years ago will soon be reality: autonomous trucks that transport goods from A to B without a driver behind the wheel. At Continental, we are picking up the pace in this area. Together with US technology company Aurora, our aim is to bring self-driving trucking systems to the roads in the USA from 2027. Let us take a look into the future and see – through the eyes of an autonomous truck – how humans and machines will work hand in hand.

The headlights pierce through the darkness. At the distribution center, the first of my colleagues are ready to leave. They’re in their designated positions, while people wearing hi-vis vests are bustling around. Some of them are steering forklift trucks around the premises. Others are loading the waiting trucks and checking the cargo. Now it’s my turn. I carefully drive into the loading bay. This always requires a great deal of precision, but it isn’t a problem for me. My sensors work hand in hand with the software. Just like I work hand in hand with the people who load me up with several pallets of cargo. The pallets contain electronic components that I need to deliver to a factory on time. One of my human colleagues does a final check, then it’s time for me to take over – and off I go.

The highway is my home. I’m an autonomous, self-driving truck designed for long-haul journeys. My mission is to deliver goods safely and efficiently. I haven’t been doing this for that long, but I do it extremely reliably. This is mainly thanks to my innovative technologies that let me navigate the roads without a driver. The number of drivers has been declining for some time now. More are retiring than are joining the profession. The long, monotonous hours behind the wheel simply don’t appeal to many people anymore. At the same time, the demand for road freight transport continues to rise. What’s more, logistics companies are under increasing cost pressures. This is one of the findings of a survey commissioned by Continental among logistics decision-makers in Germany and the USA for the IAA Transportation 2024 trade fair. According to the survey, freight forwarders in both markets are struggling with staff shortages as well as high operating costs, efficiency problems and insufficient capacity to fulfill orders. This is where I can help. Of course, it isn’t something that happened overnight. I had to learn a lot first. Millions of real and simulated test kilometers had to be completed before I could seamlessly enter the existing supply chains. But it was worth it for everyone involved.

Technologies can see better and react quicker

My route from the distribution center leads me directly onto the highway. It’s my natural habitat, so to speak. And it’s where I spend most of my time – on today’s journey too. For the first few hours, traffic is light. But it increases with every kilometer, as commuters appear. But this doesn’t affect my job. Mostly because I can see better and react quicker than human drivers. I make precise decisions thanks to the innovative technologies I have on board.

These technologies are centered around the Aurora Driver. Continental has provided much of the hardware for this hardware and software system, industrialized it and – together with Aurora – made it ready for production. Furthermore, Continental gave me the senses I need: my cameras detect people, lane markings and traffic signs, for example – even in color. My radar sensors measure the distances to other vehicles as well as their speed. They can even do this when vehicles are hidden behind other trucks, for example, so my cameras can’t yet see them. And my LiDAR sensors see objects at distances beyond the range of the human eye. These three technologies complement each other perfectly and provide data that is processed by my high-performance computer, or HPC for short.

Powerful sensors and enormous computing power

To perform all my driving functions and get from A to B autonomously, I need a powerful system of sensors. Compared with cars equipped only with driver assistance systems, I collect more complex data with my sensor system, which requires far more computing power. Right now I can see just how much I can count on it: ahead of me is the first traffic jam. Hazard lights are flashing, red brake lights are flickering. My technologies analyze the situation instantly. I brake and join the slow-moving traffic. The traffic in front of me is getting heavier. But I maintain the ideal distance, anticipating what’s coming, no matter how hectic it gets.

Human error is still the main cause of accidents around the world. That’s also why I have so many advocates. This is reflected in the representative Mobility Study 2024, conducted by the infas market research institute on behalf of Continental. In Germany, 47 percent of respondents believe that autonomous trucks like me will probably be on our roads in the near future. In the USA, this figure is 62 percent and even higher in China at 92 percent.

Never being distracted

Now I’m approaching some roadworks. The lane narrows, a car abruptly changes lane, as does a van. But my sensors see it all, detecting the vehicles’ speed and direction. Temporary road markings don’t bother me either. My computer is alert: I brake gently and stay in my lane. No problem. Unlike human drivers, I never get tired or distracted. I drive so safely and efficiently that I cut operating costs and reduce carbon emissions, helping to protect the environment along the way.

And because safety is my top priority, Continental has equipped me with a second comprehensive safety system. If my primary autonomous driving system were ever to fail – which is highly unlikely – the backup system can take over and keep me running for a prolonged period – at least until I reach the next safe location.

By the way, I’m not alone out here. Ahead and behind me, my colleagues are on the way to their destinations – some autonomously, others with human drivers. Night is now falling for them too. But, unlike humans, I don’t need to take a break to rest. I only stop briefly sometimes to refuel at one of the distribution centers along the route. This time, though, I’m driving nonstop, staying on course to reach my destination after hundreds of kilometers.

Humans and machines do what they do best

Back at the distribution center, a lot is happening again. To someone seeing this for the first time, it might look chaotic. But everything is running like clockwork and with millimeter precision. One autonomous truck after another pulls into the loading bay. Now it’s my turn. I drive safely into position. The employees don’t need to guide me. They can concentrate on unloading my freight and getting it onto the delivery vans. Because unlike me, the goods haven’t reached their destination yet. The last few kilometers to the factory – with tight turns, narrower streets and roundabouts – are still best handled by my human colleagues. Each of us does what we do best. I’ve completed my mission – and I can head off on a new one right away, without the need for a break.

Questions and Answers

Together with partner Aurora, Continental is steadily driving forward the development of driverless trucks. The aim is for the world’s first scalable, autonomous truck system to be available for use by vehicle manufacturers, freight forwarders and fleet operators by the end of 2027. With Level 4 autonomous trucks, driverless freight transport from hub to hub on US freeways is expected to be possible by 2027.

Self-driving trucks use a combination of different technologies to drive autonomously. The vehicles are equipped with many cameras and sensors, including LiDAR, radar, cameras and ultrasound sensors, in order to obtain as much information as possible from the vehicle’s surroundings. The collected sensor data is processed by AI algorithms in high-performance computers. These learning algorithms help the vehicle make decisions regarding driving tasks, such as when it needs to accelerate, brake or turn. Self-driving trucks also use detailed maps in combination with the sensor data to precisely determine their position. In addition, many autonomous trucks are equipped with advanced driver assistance systems, which ensure lane keeping and departure functions, distance management and collision avoidance.

For safe operation without human drivers, autonomous trucks require redundant driving systems that make sure the vehicle continues to function safely over a long distance even in the event that a system fails. As part of the partnership with Aurora for the world’s first scalable autonomous truck system, one of these redundancies is the backup system developed by Continental. This is a specialized secondary computer that takes over control in the event that the primary system fails. Dual sensors, control systems and communication channels also provide increased safety. To protect the systems against cyberattacks, manufacturers implement extended safety protocols and encryption technologies. The software of autonomous systems is regularly updated to close any potential security gaps and integrate new functions. Before autonomous trucks are used in real traffic, they undergo extensive testing and validation procedures.

The move toward self-driving trucks is attractive to the logistics industry for a number of reasons. In many countries, the industry is suffering from a severe shortage of drivers, while demand for goods transportation by road continues to grow. According to studies, Germany alone was short of at least 70,000 truck drivers in 2023 – and the trend is rising, since the number of those retiring each year is double that of new entrants to the profession. Other countries, particularly the USA, are also experiencing severe staff shortages. Furthermore, the switch to driverless trucks offers fleet operators the opportunity to significantly reduce operating costs and delivery times. This is because autonomous trucks greatly increase transport efficiency – with a much higher level of safety. Self-driving trucks also lower the burden on the environment: optimized driving performance reduces fuel consumption, making fleet CO2 targets achievable. In short, autonomous trucks have the potential to revolutionize the transport and logistics industry by bringing together greater efficiency, improved safety, lower operating costs and more sustainability.

Autonomous driving is in our DNA

Autonomous driving is in our DNA. At Continental, we have been working intensively on driverless mobility for more than five decades. Back in 1968, the first electronically controlled driverless test vehicle performed laps at the Contidrom test facility in Hanover, Germany. Since then, we’ve built up over 25 years of experience in sensor solutions – from single components to complete systems. In 2024 alone, we produced almost 40 million cameras and radar, ultrasonic and LiDAR sensors for assisted and automated driving functions.

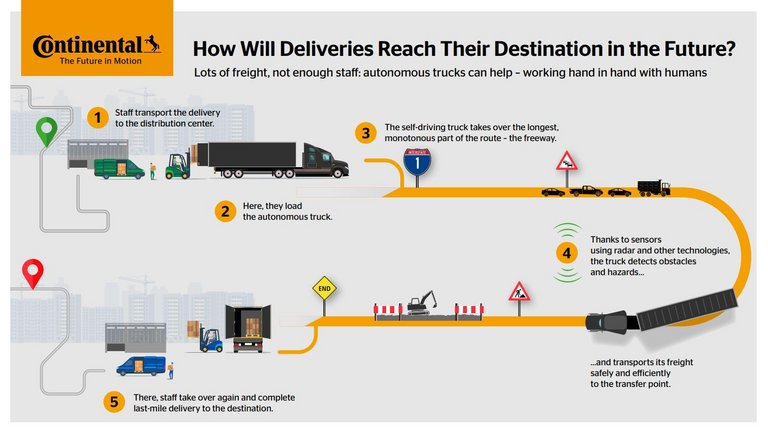

How will deliveries reach their destination in the future?

Strong partnerships for the road ahead

With more than five decades of experience in autonomous driving, we have formed strong partnerships to speed up the implementation of self-driving trucks. One of our partners is the US technology company Aurora. Together, we are working on a system solution for driverless trucks. At the heart of the system is the Aurora Driver, which we will mass produce from 2027. We provide the hardware for this system, including the central computer – our high-performance computer, also known as HPC. Aurora provides the software. We also supply the sensor technology, which forms the central nervous system and the interface to the outside world, as well as the central control units. If this system fails, a second safety system takes over control, for which we provide both the hardware and the software. Together we want to bring autonomous truck systems to US roads from 2027.

Besides Aurora, we also have a successful partnership with Ambarella Inc., a renowned manufacturer of semiconductors incorporating artificial intelligence. Together, we are developing scalable, end-to-end, AI-based software and hardware systems for assisted and automated driving.