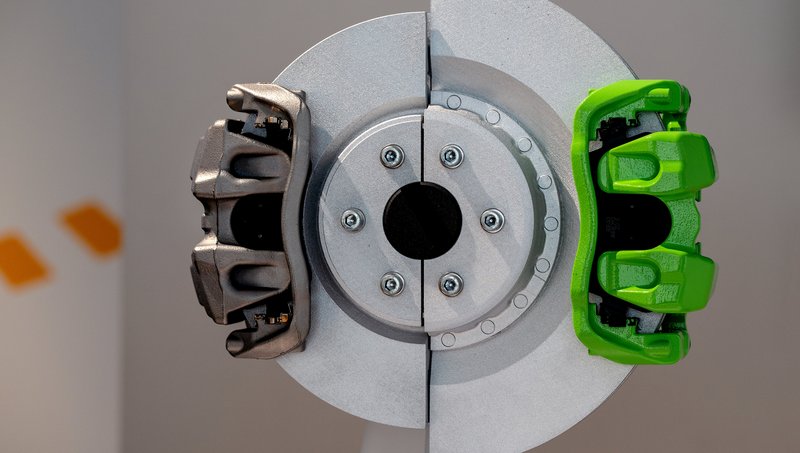

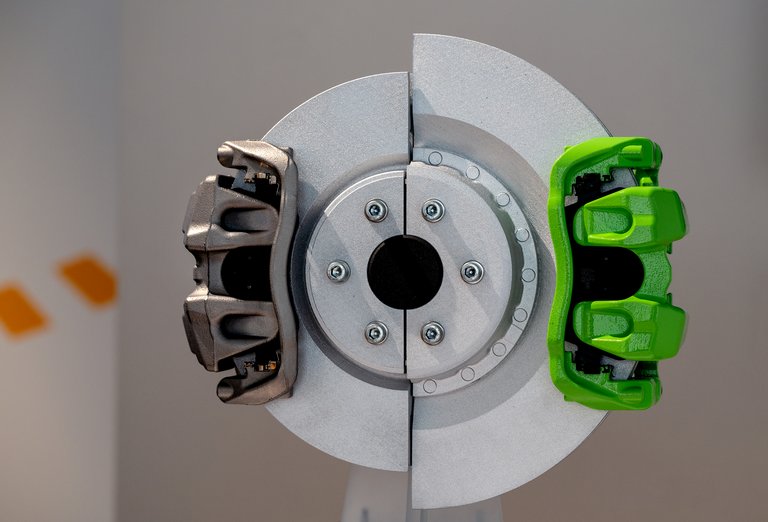

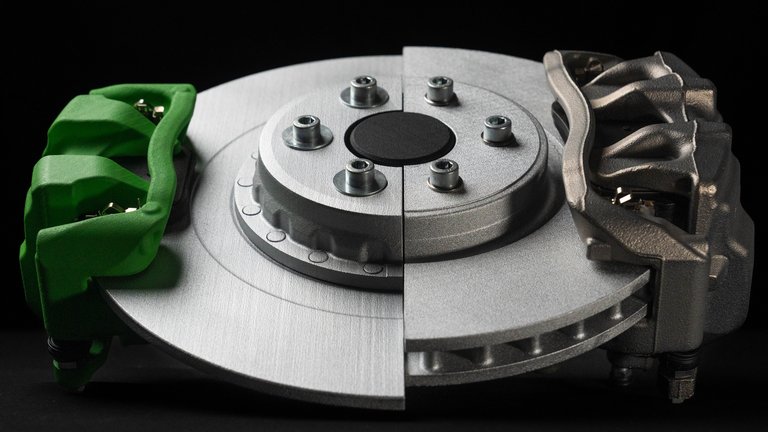

Green Caliper

Innovating the Caliper for Battery Electric Vehicles

This is where we come from: Caliper brakes with their optimum heat dissipation properties are an excellent choice particularly for the front axle (FA) in many vehicle models. Continental continues to innovate this type of brake. One main course of further development is adapting the brake design to the different requirement profile of all-electric vehicles.

+++ Reduced mass through downsizing +++ Excellent deceleration performance +++ Reduced residual torque +++ More economic and sustainable +++ |

Caliper design re-thought

Traditionally a caliper is designed to perform reliably under the toughest operating conditions, such as mountain downgrades with the car fully occupied and loaded – plus potentially a trailer attached. Two critical factors have to be considered during brake design. One is the sheer deceleration force that needs to be delivered for emergency braking. The other is the thermal performance of the brake that needs to withstand prolonged braking situations.

For a typical caliper in a conventional car with combustion engine this means that the brake is designed for the worst-case scenarios valid for this vehicle type. This is 100 % the right approach because the wheel brakes are the absolute backbone of active safety. While this applies to Battery Electric Vehicles (BEVs) as well, the worst-case scenario looks different in an all-electric car. The required maximum deceleration force is potentially even higher than that in a conventional car, because the weight of the battery adds to the vehicle mass. The frequency of friction brake application, however, is much lower.

The vast majority of deceleration events in a BEV can be covered by running the electric traction machine in its generator mode. This reduces the thermal load on the calipers because the electric machine functions almost like the retarder (= augmenting braking system) in a truck (with the difference that the retarder does not recapture kinetic force). In other words, a caliper’s thermal load in an all-electric vehicle is less critical. Preparing a caliper for this specific BEV requirement profile brings a number of advantages.

This is where we are going: Green Calipers for BEV Green Braking

The so-called Green Caliper is the result of a system approach to braking in a BEV. This floating caliper brake (FA type/pin slider) was specifically designed for the braking conditions of BEVs. As the wheel braking events go down by 80 percent and more in an electric vehicle, the thermal load on the caliper is much reduced. Even in the case of mountain downgrades, the caliper can be supported by the generator mode of the electric machine. Continental has analyzed this specific requirement profile and has adapted the design of the caliper.

- In comparison to a FA caliper for a conventional car with combustion engine, the new Green Caliper design is potentially around 2 kilograms lighter despite the use of conventional cast iron material. (Example caliper: FA63/30/11 – 330x30; Green Caliper: FA57/9/7 – 375x9)

- The pad thickness and pad area were reduced which helps with the downsizing.

- The reduced dimensions of the caliper make it possible to use a bigger and thinner grey cast disc, which can save another 3 kilograms on the disc1).

- This reduction of potentially up to 5 kilograms of (un-sprung) mass – per brake! – contributes to an electric vehicle’s range and efficiency.

- The air gap of the caliper was increased: An active pad retraction feature reduces the caliper’s residual/drag torque to <0.2 Nm and thus brings the friction losses close to zero, which can save up to 2 g of CO2 per kilometer in a combustion engine vehicle and can increase the range of a BEV in comparison to actual calipers in series production.

- The air gap was more evenly distributed through a new guiding principle and low-friction slide clips.

1)A bigger disc increases the caliper performance because the effective lever is longer (i.e., the clamping force is applied further out from the center of the disc which results in a large Reff and a better lever). This longer lever can be used to reduce the caliper piston size and length, which is part of the compact design and system approach.

The active pad retraction and a new seal groove design result in a bigger roll-back, which can be simulated by the electronic pedal of the MK C2 brake system designed for new vehicle platforms with electronic pedal. Without such technology, calipers are designed to meet a compromise between residual torque and pedal travel. There is no need for this compromise with the MK C2’s brake system and e-pedal. The Brake system’s high control rate enables a good driver experience. A high brake fluid volume in the fallback level facilitates the bigger air gaps.

The new Green Caliper design is mature and ready for application in BEVs with a typical development lead time of 2 to 3 years. The new Green Caliper design is cost competitive to conventional calipers also due to its lower mass. Bottom line: The Green Caliper design offers high braking performance with less weight and, at the same time, significantly reduced residual braking torque.