Automated Commercial Vehicles

Efficient logistics for economic development

- Driverless Hub2Hub: Heavy trucks often drive the same routes - every day, every week, every month. The congested highway sections of such routes require constant driver attention. Automation can reduce driver workload, prevent rear-end collisions, and facilitate compliance with current driving and rest time legislation.

- Total Cost of Ownership (TCO): Fleet operators can save up to one-third of TCO in truck logistics if vehicles are fully automated from hub to hub. Fleets can additionally dramatically increase their utilization per vehicle by achieving almost 24/7 operation on certain routes without the need to adhere to drivers' working hours.

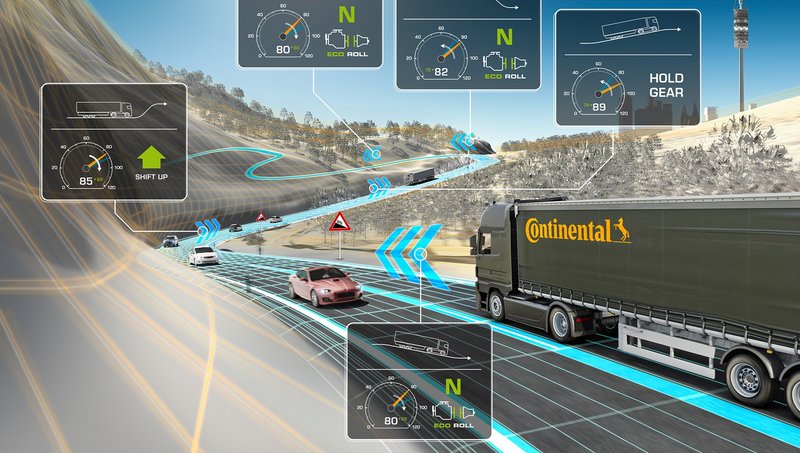

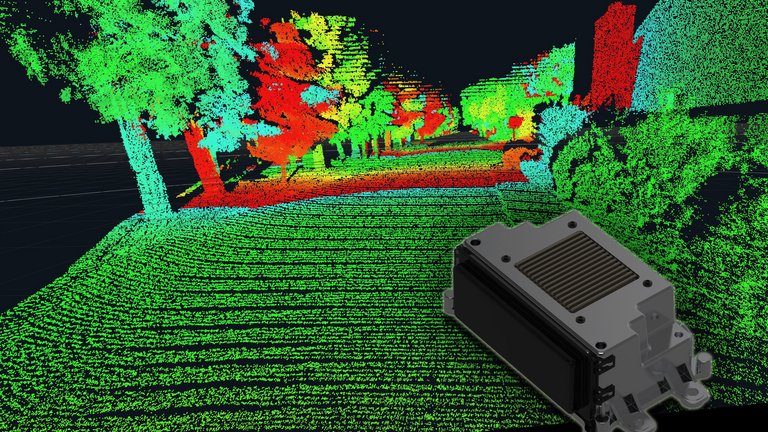

- SensePlanAct: When it comes to automated driving for trucks, Continental implements the entire effective chain and provides the vehicle with all necessary components. Sensors and high-performance computers (HPCs) for evaluation purposes are supplied directly by Continental – the pneumatic brakes are supplied by a project partner.

A conventional commercial vehicle is on the move for about nine hours a day, that means only about a third of the day. The limiting factor is the driver, who is restricted by drivers' working hours. A fully automated vehicle, on the contrary, can operate almost around the clock on certain routes. As a result, the actual benefit is significantly greater than that of a passenger car - a fully automated truck immediately generates real value, which is reflected in the total cost of ownership (TCO), being a reduced by a third. Fully automated trucks are therefore a true economic factor.

Commercial vehicles therefore have corresponding advantages in terms of development since technologies here become commercially viable much earlier. Additionally, the development of sensors and vehicle architectures for commercial vehicles can create synergies with passenger car development since components from Continental generally work for all kinds of vehicles. To maximize research and development efficiency, Continental takes a holistic approach: wherever possible, the same chain of algorithms is used for both passenger car and commercial vehicle automation.

However, the latter requires vehicle-specific adaptations. The vehicles’ dimensions alone – around 16 meters (approx. 52 ft) for truck and trailer in Europe – make covering the entire vehicle with sensors a challenge. Further challenges include the higher camera position as well as the resulting viewing angle in a truck and the dynamic characteristics of the vehicle resulting from its length and turning circle. Fuel efficiency is also a top priority for fleet operators, as fuel consumption equals cost. Fuel-saving driving strategies are therefore highly relevant. For this purpose, Continental works, among other things, with elevation profiles of the route - for efficient braking, acceleration, and coasting - and predictive braking at the end of traffic jams.

Driverless Hub2Hub

However, fully automated trucks show their full strength when securing logistics service chains. Heavy trucks (mostly truck-trailer combinations) often drive the same routes - large logistics hubs are today usually well connected near highways. Despite the often monotonous and long routes, the highway sections of such routes require the driver's constant attention, which can lead to dangerous effects such as microsleep. Automation would reduce the driver's workload, specifically preventing rear-end collisions and making it easier to comply with current driving and rest time legislation. Ultimately, fleet operators could save a third of their costs if trucks could move from hub to hub fully automated. The Hub2Hub concept could also compensate driver shortages if only subsequent distribution transports had to be covered by them. In the long term, the Hub2Hub truck solution would cover the entire journey from one loading bay to another. The major focus of function-driven development is therefore currently on the part for highway-relevant features and their continuous improvement in terms of driving performance, availability and reliability. Step by step, functions that have already been implemented are being put into practice. New features will be able to handle more complex situations, such as the handling of motorway entries and exits.

Total Cost of Ownership

Continental's industrialization expertise in technical solutions – that means its ability to offer solutions along the entire value chain in high volumes, high quality, as well as cost-efficiently - is crucial in this regard. "Continental is working on the sustainable industrialization of autonomous driving systems with the aim of relieving drivers and making driving safer. Continental ensures economic development with efficient logistics," says Dr. Andree Hohm, Head of Self Driving Car Project at Continental. In addition, Continental has the necessary experience to bring technologies in the automotive sector into series production and is not limited to one vehicle platform. "We are sustainable, solid and good - and all of it on a large scale," concludes Dr. Andree Hohm.

SensePlanAct

To maximize development efficiency, Continental is pursuing a holistic approach - not only are the algorithms almost identical, about 90 percent of the systems of passenger cars and trucks are the same. In both cases, "Sense" stands for the perception of the vehicle's condition and its environment with the help of Continental's sensors, such as innovative sensor technology for pedestrian protection, wheel speed sensors, cameras as well as short- and long-range radars. "Plan" is the derivation of possible actions and necessary decisions as performed by various electronic control units - what will happen and how must the vehicle respond? The resulting Motion Planning – what action must the vehicle take, what steering angle is required or how hard must the brakes be applied – is finally passed to "Act." In the case of a passenger car, the system intervenes directly in the vehicle's control system, for example by means of a fixed caliper, the MK C1 electro-hydraulic brake or the electric parking brake.