Winner of Continental Challenge for Polymer Recycling Solutions Crowned

- UK-based young enterprise Low Sulphur Fuels presented a unique process for recycling pre-sorted plastics as well as used tires and rubber products.

- Successful second cooperation with Innovation Network for Advanced Materials (INAM).

- Continental aims to cooperate with challenge winner to further develop the concept and explore upscaling options for industrial use.

Hanover, Germany, December 16, 2021. Continental is proud to announce the winner of the second Continental Challenge for sustainable material solutions: Low Sulphur Fuels (LSF), a young enterprise based in Amersham (UK), prevailed over more than 50 participants from across the world. Jury president Dr. Jens Högermeier, Head of Advanced Technology Development at the ContiTech business area, explains the decision: “With our challenges, we set out to find sustainable material solutions to be used on an industrial scale. The innovators at Low Sulphur Fuels have developed a convincing process that has the potential to solve a number of the unanswered questions of plastics and rubber recycling.”

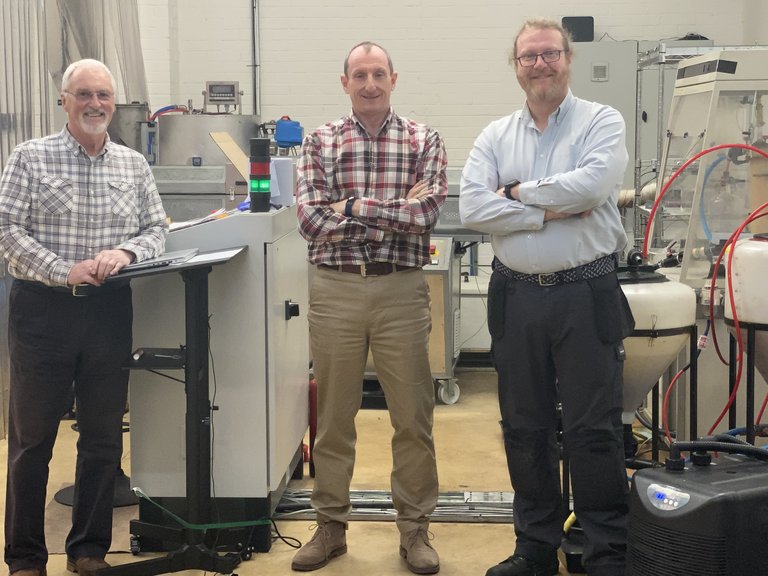

LSF’s winning idea recycles mechanically sorted plastic materials, end-of-life tires and rubber products as well as used oils through its Fast Electrochemical Process (FEP). Within this closed-loop oxidation process, the feedstock is first heated to its gas phase and then reacted with a proprietary electrolyte. The distillate is then separated and washed, resulting in a low sulphur distillate, broad-range naphta and raw carbon black which can then be used as feedstock materials for the chemical, automotive and other industries. “We are very happy that we successfully demonstrated FEP’s potential to the Continental material experts and we are looking forward to further collaborating on sustainable recycling solutions,” Glenn Halliday, co-founder and COO of LSF, comments on their company’s challenge win.

Continental Challenge draws worldwide attention

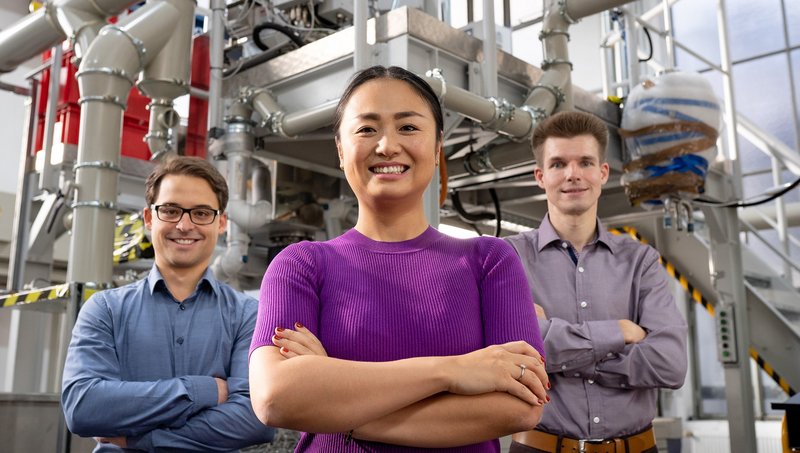

Overall, more than 50 international start-ups and university institutes had entered the second Continental Challenge where the focus lay on chemical polymer recycling solutions for engineering plastics. After that number was reduced to an initial 13 ideas, a reviewer team from across Continental’s business units took a close look at the submitted concepts and processes before that short-list was again narrowed down to four finalists. These four prospects then had the chance to finally present their idea online to more than 30 material experts around Dr. Jens Högermeier, Dr. Daniel Biensfeld (Head of Innovation Field Sustainable Materials) and Dr. Steffen Wietzke (Head of Innovation Field Thermoplastics).

Driving the execution of this Continental Challenge and determining the most promising concepts for the short list again was Continental’s partner INAM Berlin. “We were very excited to see so many interesting entries from all across the world,” said Oliver Hasse, Managing Director INAM, about the second cooperation with Continental. “We are convinced that, by enabling innovators in their efforts to make their advanced and innovative products market-ready, they can provide break-through solutions to the sustainability challenges of our times.”

Recycling essential in sustainable material development

The Continental Challenge is one of the numerous initiatives launched by the technology company as part of its comprehensive sustainability roadmap. It has decided to implement one of the most comprehensive sustainability roadmaps in the automotive supply sector, paving the way for a new, global industry benchmark with complete climate neutrality along the value chain. On the way to a sustainable economy with 100 percent climate neutrality, 100 percent emission-free mobility and industries, 100 percent circular economy and 100 percent responsible value chain by no later than 2050, the program not only includes the company's own production, but also deliberately focuses on the upstream stages and end-of-life recycling of products. “That is why, in our view, LSF’s recycling process has the most holistic potential to be used in an industrial setting,” concluded Dr. Steffen Wietzke.

In winning the Continental Challenge, LSF has now found an industry expert as a partner. Together with Continental’s material experts, they will evaluate the solution for a potential joint development as well as possible industrial upscaling.

Find out more about Low Sulphur Fuels and its solutions here.

Sébastien Bonset

Media & PR Manager, Media Coordination APAC

ContiTech