Safe, Clean, Stable: Continental Launches New Hose for the Food and Beverage Industry

- The BLAUDIECK SUPER portfolio replaces the previous product offering in the food and beverage sector and simplifies processes in procurement and applications

- Stability, robustness, hygiene: BLAUDIECK SUPER with its ultra-high molecular weight polyethylene (UPE) hose core meets all requirements of the food and beverage industry

- Continental is the first company to consistently use UPE as the sole material solution for the hose inner lining

Hanover, Germany, January 28, 2025. Continental has further developed its BLAUDIECK hose for the food and beverage industry. To offer maximum safety, cleanliness, robustness and precision, Continental’s ContiTech group sector is the first company to consistently use ultra-high molecular weight polyethylene (UPE) as the sole material solution for the hose inner lining. This makes the BLAUDIECK SUPER range the ideal choice for all applications in the food and beverage industry, replacing Continental’s previous offering in this sector. "We are delighted that with BLAUDIECK SUPER we have been able to develop a hose that effortlessly meets the strict national and international requirements of this sector," says Pius Graf, area sales manager in the business segment responsible for food & beverage hoses at Continental. BLAUDIECK SUPER hoses are available now. "The greatest advantage of our new BLAUDIECK SUPER hoses is their flexible application in all areas of the food and beverage industry," explains Pius Graf. "Not only are we increasing process safety and meeting the increasingly strict standard requirements that apply in this sector, especially in Europe. By focusing on UPE as material for the hose core we are also making it easier for buyers and users to find the right hose for each individual situation. After all, BLAUDIECK SUPER is a suitable solution for all situations."

Unique UPE inner lining for all applications

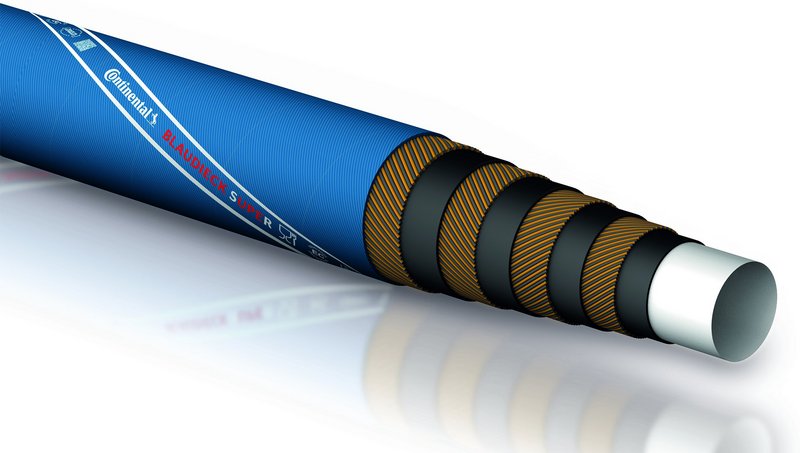

In the food and beverage industry, safety is the best recipe. The BLAUDIECK SUPER hose was developed specifically with this in mind. Its white, non-porous and plasticizer-free UPE core features specific properties that make it an appropriate choice for all applications, even in the challenging conditions of dairies, breweries and the food industry.

The low permeability of the hose inner lining protects the medium against contamination. At the same time, it makes the hose even more resistant to certain media as well as temperatures up to 95 °C and for short time periods up to 110 °C. This means it is even more durable, easy to maintain and cost effective. Hoses with UPE can be easily cleaned with up to 130 °C saturated steam. As a result, users can effortlessly meet the high hygiene requirements in the food and beverage industry and efficiently switch from one medium to another. And finally, the homogeneous UPE inner lining provides a consistently stable inner diameter, eliminating the risk of impurities and bacterial nests.

Different designs for maximum flexibility

Besides the classic hose with a UPE inner lining, NBR (Nitrile Butadiene Rubber) outer coating and pressure-bearing component made of synthetic fibers, the BLAUDIECK SUPER also has an integrated steel wire spiral for particularly demanding suction processes. An electrically conductive version is available for use in potentially explosive areas featuring an integrated Ohm conductive strip. Offering internal and external resistance to oils and fats, it is also resistant to common cleaning and disinfecting agents as well as chemicals (according to the Continental resistance list). The operating pressure is 16 bar (232 psi).

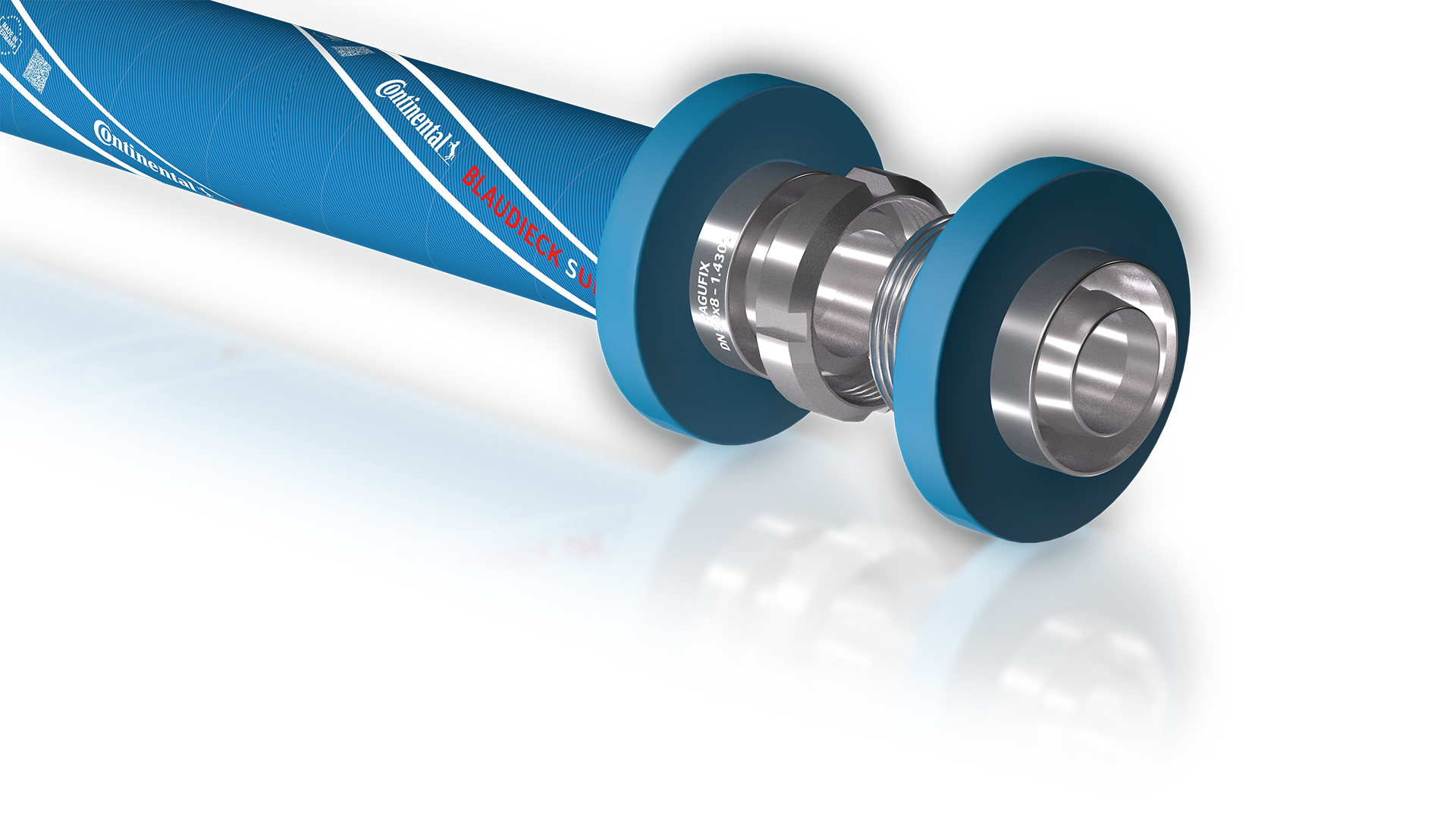

Continental offers the BLAUDIECK SUPER range in all common nominal inner diameters, from 19 to 100 millimeters (DN 19 – DN 100) and in a standard length of 40 meters. Individual lengths and ready-pressed hose lines including fittings are also possible. The connection technology plays a major role in the food and beverage industry. With the PAGUFIX swaged fitting and the PAGUCLAMP half-shell fitting, Continental also offers the ideal solution for the BLAUDIECK SUPER range. The geometry is adapted to the hose construction to prevent damage to the hose inner lining during the fitting process and to make sure that the hose end is completely sealed.