Continental Supports Hyperloop Technology as a Logistics Solution of the Future

- New mobility concepts: sustainable, fast and cost-effective transport of goods possible via Hyperloop

- Collaboration with talented young people at the Emden/Leer University of Applied Sciences and the University of Oldenburg

- Special belts made of carbon cord and polyurethane from Continental move HyperPodX

Hanover, Berlin, Germany, September 17, 2018. Technology company Continental is actively promoting the future of logistics and is involved in Hyperloop development. Most recently, the Group supported the research work of some talented young people. For the “HyperPodX” project, students of the cooperative Engineering Physics course at the Emden/Leer University of Applied Sciences and the University of Oldenburg have developed a Hyperloop as part of a competition organized by U.S. company SpaceX. The drive is provided by a high-performance belt from Continental. “The future of mobility is in rail transport. Safe, reliable and, above all, fast transport will be essential for the logistics of the future. The existing infrastructure will hardly be able to cover the rising flows of goods. The industry needs new, efficient alternatives,” explained Hans-Jürgen Duensing, member of the Continental Executive Board. “We therefore see a promising future for technology in new rail transport solutions such as the Hyperloop, and are passing on our expertise built up over more than 90 years in industry to the engineers of tomorrow.”

Low aerodynamic resistance ensures extreme speeds

The Hyperloop system would allow for the transport of people and goods at speeds of more than 1,000 km/h – similar to those achieved by aircraft. The advantage over air transport is that the Hyperloop is much more environmentally friendly and could be used like a subway. The technological concept is based on the principle of reducing the usual resistance of regular trains in tunnel-like tubes so that the vehicles can achieve much higher speeds. Aerodynamic resistance in particular is reduced to almost zero. The air pressure in the tubes corresponds to only one percent of the usual atmospheric air pressure. In addition, the Hyperloop comes without wheels, which means that they are not there to cause friction. Instead, the capsule-shaped vehicles use magnetic levitation technology or air cushions to move.

Low aerodynamic resistance ensures extreme speeds

The Hyperloop system would allow for the transport of people and goods at speeds of more than 1,000 km/h – similar to those achieved by aircraft. The advantage over air transport is that the Hyperloop is much more environmentally friendly and could be used like a subway. The technological concept is based on the principle of reducing the usual resistance of regular trains in tunnel-like tubes so that the vehicles can achieve much higher speeds. Aerodynamic resistance in particular is reduced to almost zero. The air pressure in the tubes corresponds to only one percent of the usual atmospheric air pressure. In addition, the Hyperloop comes without wheels, which means that they are not there to cause friction. Instead, the capsule-shaped vehicles use magnetic levitation technology or air cushions to move.

Real Hyperloop projects conceivable in the near future

A distance of 1,000 kilometers in an hour? For the logistics industry, the idea of using such a means of transport between the global production sites opens up many new opportunities in logistics. “It will take another three to five years before the first Hyperloop is actually used for transporting goods,” predicts Professor Walter Neu, Hyperloop expert at the Emden/Leer University of Applied Sciences. “There are currently several test tracks under construction, such as in France and the United Arab Emirates, while a route between Vienna and Prague is also being discussed.”

If the Hyperloop technology proves itself there and real projects are implemented, companies will benefit from goods being transported much more quickly than they are on current rail vehicles or trucks. Due to its low resistance, the Hyperloop requires only a fraction of the energy and is therefore an equally cost-effective and sustainable solution. The system also takes some of the strain off the road and rail network. In the long term, the Hyperloop may also be used in passenger transport.

Real Hyperloop projects conceivable in the near future

A distance of 1,000 kilometers in an hour? For the logistics industry, the idea of using such a means of transport between the global production sites opens up many new opportunities in logistics. “It will take another three to five years before the first Hyperloop is actually used for transporting goods,” predicts Professor Walter Neu, Hyperloop expert at the Emden/Leer University of Applied Sciences. “There are currently several test tracks under construction, such as in France and the United Arab Emirates, while a route between Vienna and Prague is also being discussed.”

If the Hyperloop technology proves itself there and real projects are implemented, companies will benefit from goods being transported much more quickly than they are on current rail vehicles or trucks. Due to its low resistance, the Hyperloop requires only a fraction of the energy and is therefore an equally cost-effective and sustainable solution. The system also takes some of the strain off the road and rail network. In the long term, the Hyperloop may also be used in passenger transport.

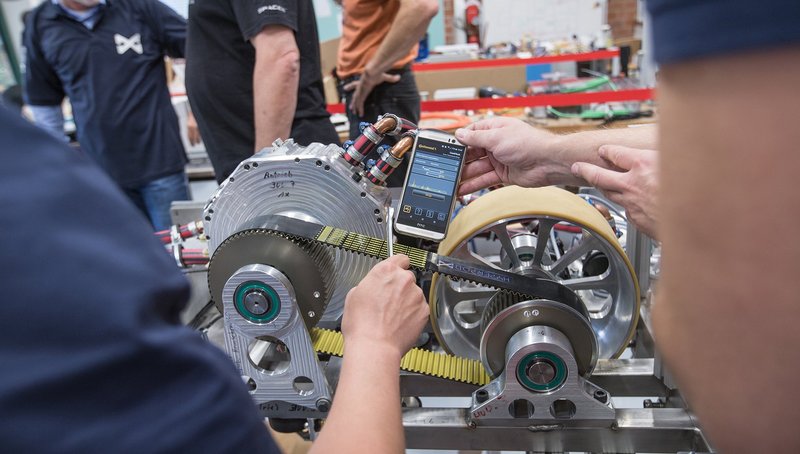

Continental drive belt meets Hyperloop requirements

Continental recognized the potential of the technology at an early stage and is working together with talented young people in development work. One example is its current project with students from the Emden/Leer University of Applied Sciences and the University of Oldenburg. Under the leadership of Professors Walter Neu and Thomas Schüning, they have spent the last nine months thinking about how to reach the necessary high speeds safely and reliably. Their specific task for the SpaceX competition was to develop a Hyperloop prototype with a drive system that can achieve high acceleration in a vacuum, can brake and has its own power supply. The students met this challenge with an electric motor with an output of 170 kilowatts. This takes the 250 kg prototype to a top speed of up to 500 km/h. “We needed high torque and a very powerful belt for our drive system. Continental first advised us and finally provided us with the appropriate special belt, which can reliably handle the high acceleration forces in the Hyperloop and its use in a vacuum thanks to its material properties,” said Neu of the requirements.

Alexander Behmann, application engineer at Continental, added, “With its design of carbon cord and polyurethane, the belt is extremely energy-efficient as well as very narrow and therefore extremely lightweight. It is also very reliable without maintenance. And these aspects – power, reliability and low weight – are precisely what a HyperPod needs. We were thus able to offer the students a suitable solution.” The belt has already successfully passed its first test. The runs on the SpaceX test track in Los Angeles went well and the team of mechanical and electrical engineering students from the Emden/Leer University of Applied Sciences placed in the top ten of the competition.

Sébastien Bonset

Media & PR Manager, Media Coordination APAC

ContiTech