It’s All About the Mix – for Beer Exports and Industrial Hoses

Hanover, Germany, November 8, 2021. Hops, barley malt and clear water are the essential ingredients for one of the world’s most popular beverages: Beer. Every year, the world’s largest hop wholesaler, the BarthHaas Group in Nuremberg, Germany, provides the most important statistics, facts and figures about the brewing industry in its annual report. According to BarthHaas, around 1.8 billion hectoliters of beer were brewed in 172 countries in 2020. This corresponds to 36 million 50-liter barrels, or 246 times the amount of beer consumed at Munich’s famous Oktoberfest. In 2019, no fewer than 7.3 million one liter beer mugs were filled at the last beer festival before the corona virus pandemic.

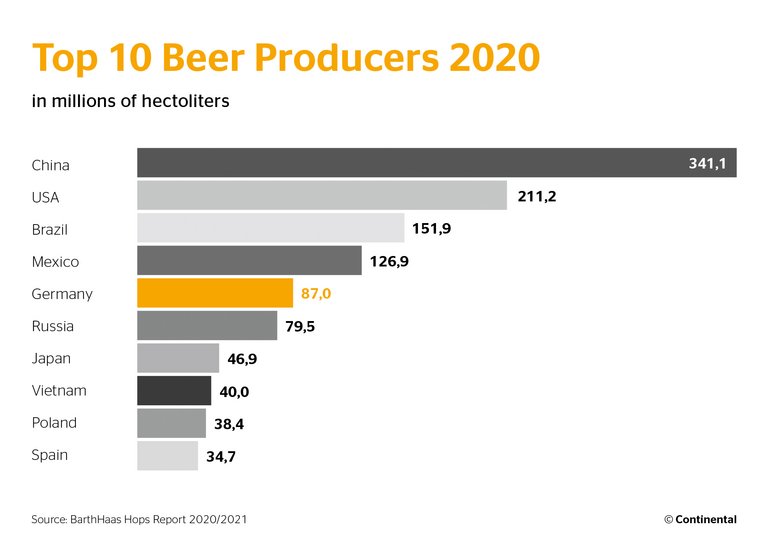

However, it is not Germany that leads the way in beer production: In 2020, the world’s largest producers were China, the USA, Brazil, and Mexico. Germany takes fifth place, ahead of Russia, Japan, Vietnam, Poland and Spain. While the trend toward more and more types and specialty beers is apparent in Germany, traditional beers brewed according to the German Reinheitsgebot (purity law) are in demand on the global market. Despite this diversity, many beers from all over the world have one thing in common: They flow through food safe special purpose hoses from Continental before they reach the tap.

Bavarian brewing traditions and modern strategies also coincide at OeTTINGER

The OeTTINGER brewery also relies on hose solutions from Continental and has enjoyed longstanding success on international markets as a “global brand made in Germany”. The Oettingen, Gotha, Mönchengladbach and Braunschweig brewing plants produce around 40 specialty beers and mixed beers as well as soft drinks – for the domestic market and worldwide export. The origins of the OeTTINGER brewery date back to 1731. Over the past 60 years, the Kollmar owner family has developed the company from a small village brewery in the Donau-Ries region to one of Germany’s largest beer brands measured in terms of output and number 25 among the world’s largest breweries. “My family firmly has faith in one of the most beautiful products in the world: Beer. Beer is part of our family history and is, so to speak, in our DNA,” says Pia Kollmar, managing partner at the brewery.

At the start of the new millennium, the Bavarian family-owned company dipped its toe in international business, scoring an impressive success. Today, its beer is consumed in more than 100 countries around the world, with around one third of annual production going for export. This puts OeTTINGER in 2nd place in the export ranking of German brewers. The most important foreign markets for the family-owned company are Italy, China, Belgium, Switzerland, Russia and the Netherlands. Country-specific preferences are obvious: While the “Original OeTTINGER Super Forte” strong beer is mainly delivered to China, Italy, and Peru, “Naturally Cloudy Original OeTTINGER Radler” is popular in Taiwan, Uruguay, and Ecuador.

Overall, however, the traditional wheat beer, export and pils types dominate the brewery’s export portfolio; mixed drinks are considered niche products. After all, German beer enjoys a worldwide reputation for its pure taste, purity and natural ingredients. In fact, the German purity law is the oldest food law still in force today. As early as 1516, the Dukes of Bavaria decreed that beer should be brewed exclusively from barley, hops and water.

Hoses from Continental withstand the challenges of everyday brewing

Not only do the high-quality ingredients required under the purity law contribute to the taste experience, but food safe materials and hygiene are just as important in the brewing process. At OeTTINGER’s highly automated manufacturing facilities, special-purpose hoses such as the “Purple Snake” and the “Aquapal” from Continental play an important role in food safety. The technology company supplies not only hoses, but also complete lines with crimped fittings. These complete solutions are particularly hygienic because both components fit seamlessly into one another; there is almost no place for germs to hide and turbulence is almost completely ruled out. The fixed, hygienically flawless connection between the rubber tubing and the fitting can withstand pressures of up to 16 bar with triple safety.

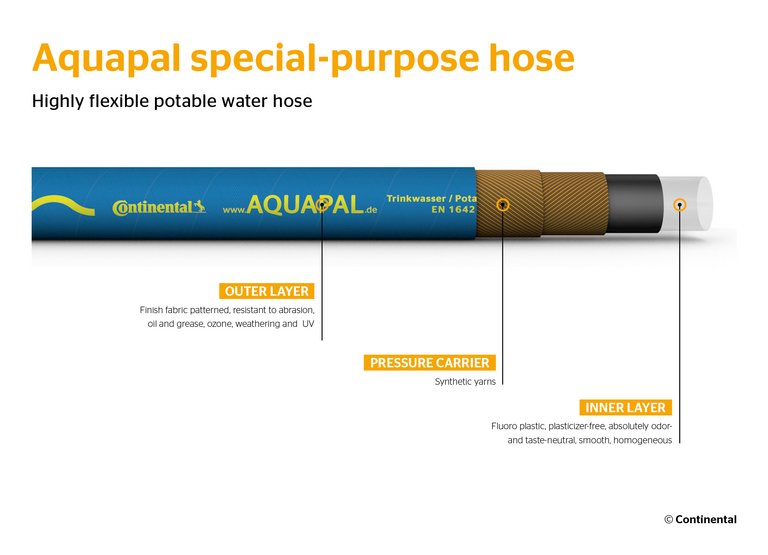

Of particular importance for use in the food industry is the fact that the smooth inner liner of Continental hoses, referred to as the soul of the hose, is absolutely odorless and taste-neutral. It conforms to the XXI recommendations of the German Federal Institute for Risk Assessment (BfR) as well as the directives of the Food and Drug Administration (FDA) in the US. The special elastomer inner layer in the “Purple Snake” is completely non-porous. Synthetic yarns with two spiralized copper strands have proven their worth as pressure carriers. The outer layer, in turn, is made of a special abrasion-resistant elastomer and, with its ribbed surface, is ozone-, weather-, and UV-resistant. In the “Aquapal”, the soul of the hose is made from plasticizer-free fluoro plastic. As with the “Purple Snake”, synthetic yarn is used as a pressure carrier. The characteristic blue hose cover of the “Aquapal” is resistant to oils and greases, as well as abrasion and also ozone, weathering and UV impact.

“Our material blends have been adapted to market requirements, ensuring maximum safety over a long period of use,” explains Georg Bester, who is responsible for food hose sales at Continental and an expert in technical consulting. Bester’s many years of experience mean he knows exactly the stringent requirements for hose solutions: “Hoses in breweries are used and cleaned extremely frequently – so they have to withstand high levels of stress. Our hoses can withstand temperatures of up to +95°C and are chemical-resistant and robust i.e., designed for challenging applications. At the same time, the hoses can be used very flexibly. They are suitable for a wide range of media – various types of beer, mixed beer and soft drinks, alkalis and cleaning agents,” explains Bester.

Sven Willim, deputy production manager at the OeTTINGER Brewery in Möchengladbach, confirms the remarkable properties of Continental’s food hoses produced in Korbach in the German state Hesse. “Our employees can give the hoses a lot of punishment, laying lines spontaneously and sometimes dragging them over the floor without causing them to twist or get damaged,” explains Willim. In some cases, Continental hoses are used for up to ten years – without compromising on quality: “This is confirmed time and again by regular microbiological samples of liquids and hose tests by independent organizations.”

Wolfgang Reinert

Head of Media & Public Relations

ContiTech