Continental Invests in Production Systems for Agricultural Industry at Hanover Site

- Technology company expands power transmission belt production and invests more than 2.5 million euros in agriculture sector, a key business for the future

- New production line raises production output and boosts competitiveness

- Test rig developed in-house tests load capacity, robustness and quality of variable-speed belts

Hanover, August 22, 2019. Technology company Continental is expanding its capacity for the agriculture sector at its Hanover site, investing more than 2.5 million euros in new systems for drive components for agricultural applications. Continental regards the agricultural industry as one of the key industries of the future. It has therefore installed a new production line and a new test rig at its Hanover-Vahrenwald plant. This is enabling the company to raise its production output, extend the range of applications for the belts and increase its competitiveness.

“There is no future without agriculture. Our investment is therefore a clear signal of our future intent and an important step on our growth journey,” says Claudia Holtkemper, who heads up the business unit for power transmission belts and components at Continental. “The constant growth in the world population means that the demand for harvest products is increasing globally and, with it, the demand for innovative components and systems for high-tech equipment and agricultural machines. We offer our customers innovative products and services plus individually tailored solutions for enhanced efficiency in the field.”

New application fields for high-performance belts

The new line has already been commissioned. Among the belts Continental is manufacturing on it are variable-speed belts – including a new, smart type with an integral sensor that enables predictive, proactive maintenance. These belts are used as high-performance belts in agricultural machines such as combine harvesters to provide reliable power transmission – even under extreme conditions such as dirt, dust, humidity, heat and cold. The installation of the new line means that belts can be manufactured in widths of up to 40 inches – 10 inches more than the previous maximum. Thanks to this new specification, the power transmission belts now represent an alternative to chain drives in even more agricultural applications.

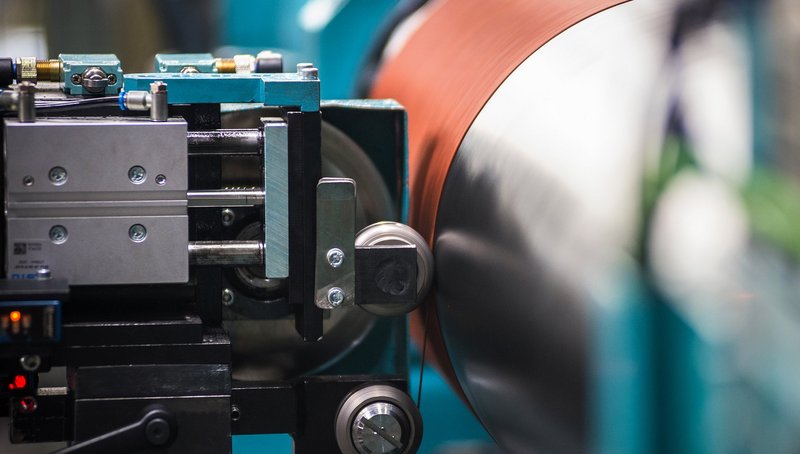

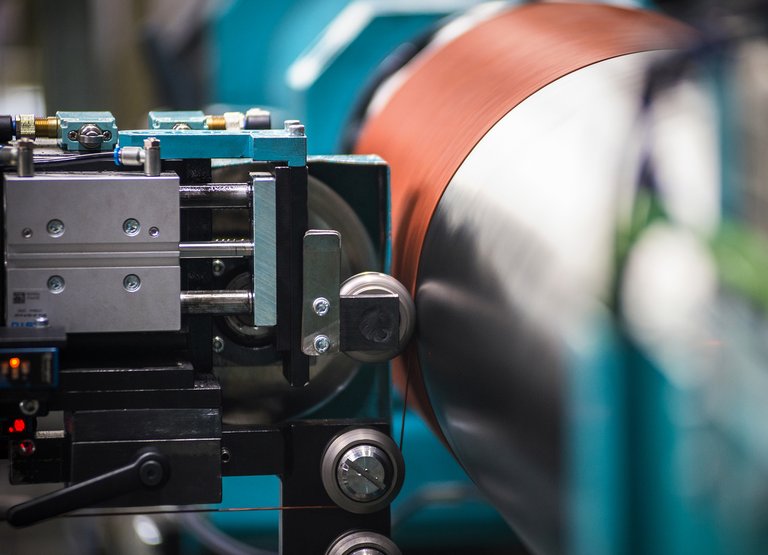

The newly installed test rig is equipped with leading-edge technology to test the load capacity and robustness of the variable-speed belts up to a power output of 200 kilowatts. In this state-of-the-art facility, Continental is expanding its investment in quality-assurance measures to ensure the best possible compliance with complex customer requirements.

Today’s agricultural machines such as combine harvesters, forage harvesters and tractors are complex, high-performance units that are extremely demanding, especially on their drive system components. To meet that need, Continental offers a comprehensive portfolio of wrapped V-belts, banded V-belts, variable-speed belts and multiple V-ribbed belts, while also developing customer-specific solutions.

Here you‘ll find all information on Agritechnica.

Wolfgang Reinert

Head of Media & Public Relations

ContiTech