Invisible Markers in Tires Ensure Greater Transparency in the Natural Rubber Supply Chain

- Marker substance allows geographical origin of raw materials to be verified

- Field testing successfully completed – marker substance can be verified beyond doubt throughout tire production process

- In the long term, Continental plans to use the marker substance on a large scale in rubber products

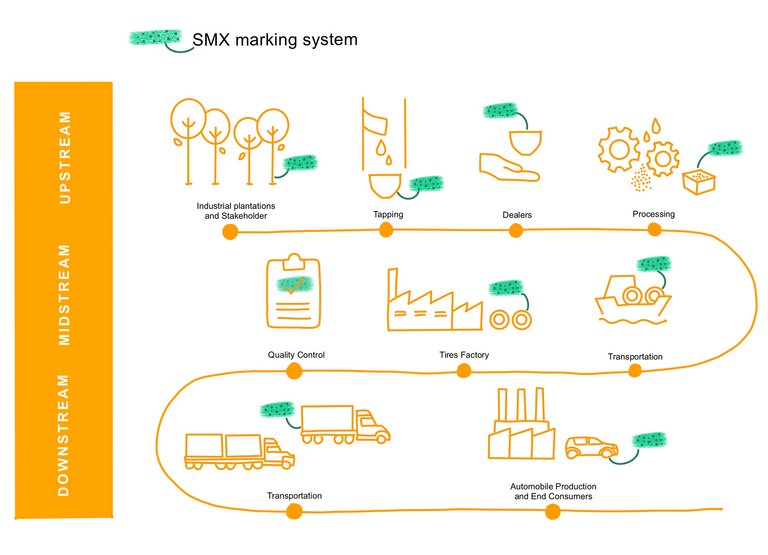

Hanover, Germany, December 7, 2022. Continental and Security Matters (SMX), an innovative tech platform specializing in digital tracking using unalterable chemical-based barcodes, have succeeded for the first time in verifying beyond doubt a marker substance for natural rubber in a tire, and thus throughout the entire production process. The dedicated marker technology, which both companies optimized for use in natural rubber, is designed to create greater transparency along the entire value chain of tires and technical rubber products from Continental. Provided with special security features, the use of the marker substances enables the invisible marking of natural rubber with information on its geographical origin. This means, for example, that responsibly sourced natural rubber and its origin can be verified at every stage of the supply chain all the way to the customer. By doing so, Continental is further strengthening its pioneering role in its commitment to greater transparency along its supply chain. By 2050 at the latest, all materials that Continental uses in its tire production will originate from responsible sources.

“We see huge potential in marker technology. In the future, it will help us to ensure that the natural rubber we use in our tires is grown and sourced entirely responsibly,” says Claus Petschick, Head of Sustainability at Continental Tires. “Over the long term, we believe that marker technology could help to make the sometimes highly complex processes in our supply chains more transparent and verifiable. With Security Matters, we have an innovative partner for the development and trialing of marker technology by our side.”

“Together with Continental, SMX will use marker, reader and digital technology to further improve the transparency of the natural rubber supply chain and enable sustainability and circularity,” says Haggai Alon, CEO of SMX.

In the successfully completed field test, the marker substance underwent and passed a real test of resilience. The substance was added to responsibly grown latex during harvesting and withstood not only the intensive preparations involved in the production of natural rubber but also the tire manufacturing process itself.

In the manufactured tire, the data was retrieved using special, purpose-built software and a reader, and correctly interpreted. The appearance and performance of a bicycle tire containing the invisible marker remained unchanged.

Smallholders taught how to use the marker substance

For the field test, natural rubber grown as part of a joint project run by Continental and the German development aid agency ‘Deutsche Gesellschaft für Internationale Zusammenarbeit’ (GIZ) in the Indonesian province of West Kalimantan was used and provided with the markers. The project focuses on education and digitalization as the keys to establishing sustainable supply chains for natural rubber. Local smallholders were taught how the marker substances work and in what concentration they need to be added to the latex.

Clear ambition for the future: large-scale use in rubber products

Now that the technology has passed its first test of resilience, Continental is planning to use the new marker technology on a larger scale in the future during the process of sourcing its rubber and also to integrate it in other rubber products. As part of the industrialization of this technology, it is conceivable to link the markers with blockchain technology, which is particularly tamper-proof. This could provide additional support for tamper-free monitoring of compliance with quality standards and quality criteria along the complex supply chain of natural rubber.

All Continental tires to be made from sustainable materials by 2050 at the latest

Continental Tires is pursuing a holistic approach to sustainability across all phases of the tire value chain and has set itself the mission of becoming the most progressive tire company in terms of environmental and social responsibility by 2030. By 2050 at the latest, the company is aiming to use 100 percent sustainably produced materials in its tires and wants to achieve full climate-neutrality along its entire value chain. Both Continental and Security Matters are members of the industry initiative Global Platform for Sustainable Natural Rubber (GPSNR), which connects key players from business and civil society in the natural rubber sector. As members, they work to actively improve sustainability in the natural rubber sector all over the world.

The start of the collaboration between Continental and Security Matters was initiated by Continental's own start-up organization co-pace. Its goal is to broker, promote and leverage connections between emerging companies and Continental’s business units. Focus areas of the global team of technology experts at co-pace are advanced materials, autonomous systems, artificial intelligence, data security, next-generation batteries, advanced drive systems or smart cities.

Henry Schniewind

Head of External Communications

Continental Tires

Laura Averbeck

Communications Manager Sustainability

Continental Tires