Continental Optimizes Intralogistics with Robots, Tires and Digital Solutions

LogiMAT 2022

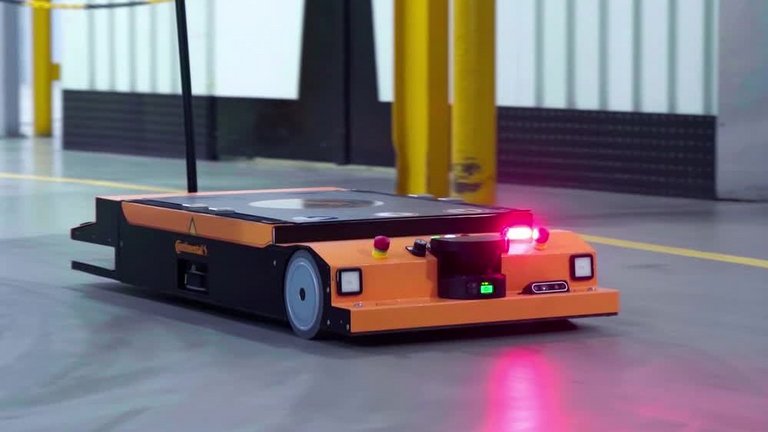

- In-house-developed autonomous transport vehicle optimizes material transport in production. Volume production planned for 2022 after completion of the trial phase

- Holistic product range for warehousing and port logistics: Continental presents its current tire portfolio, its digital solutions and its material handling solutions

- International trade show for intralogistics solutions and process management in Stuttgart from May 31 to June 2, 2022

Hanover, Germany, April 8, 2022. LogiMAT, the international trade show for intralogistics solutions and process management, will set new standards from May 31 to June 2, 2022 in Stuttgart. The technology company Continental will also be exhibiting at the largest annual intralogistics trade show in Europe. Under the slogan “Shaping the Future of Intralogistics” the company will showcase pioneering solutions from the fields of Autonomous Mobile Robots (AMR) as well as tires, digital solutions and material handling solutions.

“As a tire manufacturer, automotive supplier and manufacturer of industrial production solutions, we have a completely unique profile to support the intralogistics industry,” said Mario Branco, head of Business Development Off-Highway at Continental. “We are thus helping the intralogistics industry to quickly and effectively integrate suitable new technologies into their products, thereby significantly increasing value creation.” Employees from all areas of Continental relevant to intralogistics will be welcoming visitors at stand EF 15 in Hall 2.

AMR – an autonomous robot for logistics tasks on the shop floor

Continental is showcasing a state-of-the-art, autonomously driving transport vehicle developed in-house that further increases efficiency in production operations. This Autonomous Mobile Robot (AMR) automates the flow of materials in production plants, warehouses or logistics centers. The robust vehicle is equipped with proven technologies: lidar sensors for 360-degree detection of the environment, 3D camera systems, intelligent software and an optional ultra-wideband transmitter for precise live tracking of the AMR in the fleet make the robotic vehicle a valuable employee. It independently executes transport orders, can avoid obstacles and calculate alternative routes. An optional fleet management system can coordinate a larger fleet of AMRs.

Continental initially designed the autonomously operating vehicle for its own benefit: Engineers at the technology company could not find a suitable solution on the market to make the material flow and handling of heavy product components at its own plants more efficient. “We developed a customized robotics solution that is currently being integrated very successfully into everyday production at our plants for hydraulic brake systems in Slovakia and China. The intelligent transport robot will also be mass-produced for external customers from this year,” said Pierre Pomper, Head of Autonomous Mobile Robots at Continental .

Heavy-duty timing belts for automated storage and retrieval systems

High-rise racking stores are the beating heart of many logistics processes. Filling them and removing goods from them effectively is a major challenge that is increasingly being met by automated storage and retrieval systems with belt drives. As key elements in intralogistics processes, they position goods quickly and precisely. Together with a partner, Continental has developed a new drive technology that is based on the block-and-tackle principle and works with a deflected belt drive. Here, a synchrodrive timing belt offers several advantages over the rope technology that is often used: minimal wear, less maintenance, shorter positioning times and longer change intervals. The belt technology does not require any lubrication and has already proven beneficial in series production – under large loads as well as in the low-temperature range at temperatures as low as 30 degrees below zero. Continental makes the compounds needed to produce the corresponding belts in-house.

Continental presents current tire portfolio for logistics and port operations

Whether the transport of heavy loads is in demand, longer distances have to be covered or automated vehicles in material handling are involved, Continental will be presenting its current tire portfolio for the logistics and port industry and its digital solutions for more efficient tire use at LogiMAT 2022. Driven by the pandemic, hygiene regulations in particular have risen sharply in the pharmaceutical and food industries, and in a wide range of other industries. Continental is meeting these requirements with its non-marking tires, which it will also be showing at the trade show. After all, it is precisely in highly hygienic production conditions that driving and braking marks should be reduced as far as possible. Tires such as the SC20, CS20 and CSEasy as non-marking versions thus visibly contribute to a cleaner and more hygienic working environment.

Continental will also be bringing its new three-brand strategy to life at LogiMAT. Under the Continental, General Tire and Barum brands, Continental offers a customized portfolio of robust solid tires for a variety of industrial applications and customer requirements. Regardless of whether for the highest requirements, such as in 24/7 use, or for areas of application with lower intensities.

Like a bird: ProViu 360 gives a complete surround view of the industrial truck

Drivers of industrial trucks in a warehouse can’t have their eyes everywhere. At the same time, however, accidents must absolutely be avoided. Colleagues walking around on the shop floor need to be protected. Collisions with vertical rack struts can cause extremely serious damage to property. The ProViu 360 digital camera system provides a bird’s eye view of the vehicle and its surroundings. Four 1.3-megapixel cameras supply images in HD resolution, which are displayed on a 10-inch HD touchscreen. In collaboration with OEM customers, Continental’s engineers can develop numerous, even highly specialized solutions based on the ProViu 360 system. Special applications are possible, for example, which are only required in certain models within a portfolio. In addition to various warning functions, the development agenda for engineers and programmers also includes the fusion of camera and radar information and the display of augmented reality content.

A better view of the working environment is also provided by Continental’s new work lights for industrial trucks. All major applications are covered by the four variants – Spot, Wide, Ultra-wide and Flood. Their aluminum housings are designed for off-road use and are appropriately protected against water and dust ingress in accordance with the IP6K8 standard. The lights withstand temperatures from -40 °C to +90 °C and are protected against strong vibrations. Their flexible mounting system enables retrofitting at many different positions on the industrial trucks.

Sören Pinkow

Media Spokesperson Autonomous Mobility and Commercial Vehicles

Continental Automotive

Julia Reinhold

Communications Manager Commercial Specialty Tires

Specialty Tires

Continental Tires

- +49 511 938-2570

Wolfgang Reinert

Head of Media & Public Relations

ContiTech

Valerie Libercka

Media Spokesperson Smart Mobility

Continental Automotive

"A good fit for the team, the new one"

A revolution in material flow automation

Continental’s new Autonomous Mobile Robot (AMR) is THE innovation in intralogistics. Our AMR can be a valuable team player for you that streamlines your logistics processes. Guided by smart software, and incorporating leading-edge hardware, the new one will be a reliable top-performer.

More about the Autonomous Mobile Robot