Electric Mobility and Tires: White Paper Provides Information on Tire Technology for Electric Vehicles

- Electric mobility is leading to a shift in focus in tire development: rolling resistance, load capacity and noise levels are increasingly in the spotlight

- Comprehensive information package from Continental offers insights into tire development for alternative drive systems

- New white paper describes initial pilot projects and real-world experiences

Hanover, Germany, November 11, 2021. Vehicle manufacturers and suppliers, indeed the entire mobility industry, are working to make mobility and the value chain as a whole more sustainable in the future. Electric vehicles are key to greener, future-proof mobility. The company was quick to focus its tire development work on the new requirements of alternative drive systems. As a result, it unveiled a specially adapted tire for the electric and hybrid vehicle market as early as 2011 with the presentation of the Conti.eContact at the IAA Commercial Vehicle Show. Today, the premium tire manufacturer is bringing its many decades of tire development experience together with the findings obtained from real-world testing and various collaborations in order to ensure its entire tire portfolio also suits the specific requirements of non-ICE (internal combustion engine) drive systems. The new ‘Electric Mobility and Tires’ white paper offers a quick and sound introduction to the topic of tire development for electric vehicles. It compiles relevant facts and figures, makes interesting statements and offers stimulating ideas for research topics, all accompanied by attractive photos. The white paper’s 30 pages are divided into chapters covering the electric mobility trend, tires for electric vehicles, tire development, and finally pilot projects and collaborations. Each chapter begins with an infographic that provides a brief overview.

The same but with a difference: tires for electric vehicles

“Tires for electric vehicles and those for conventionally powered vehicles are essentially the same. However, electrification changes significantly the conditions in which the tires have to work,” says Annika Lorenz, Head of Fleet Solutions Germany at Continental. There are already 10 million electric cars on the world’s roads. However, the majority of vehicles will be running on internal combustion engines for a while yet; electric vehicles account for nearly four percent of the German market, but this is dwarfed by the roughly 96 percent share posted by gasoline and diesel vehicles. “In the fleet business, in particular, the focus on electric vehicles will gain greater momentum,” continues Lorenz.

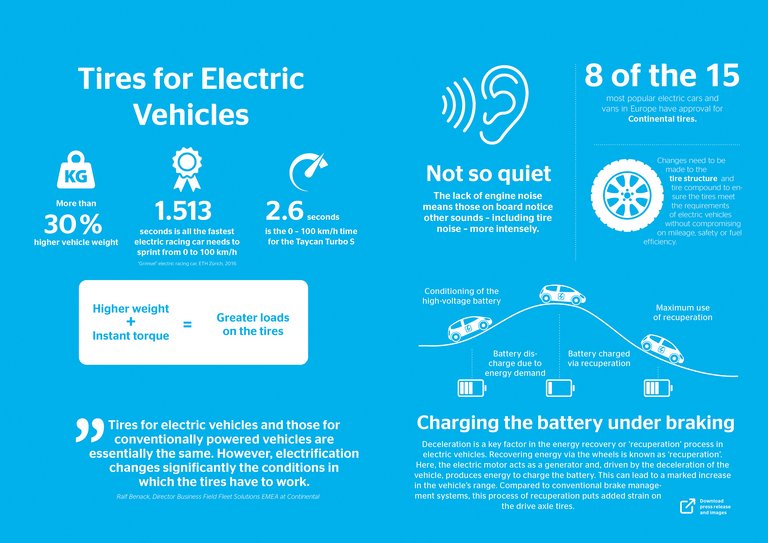

When it comes to tires, the same essentially applies for a highly efficient electric vehicle as for a low-emission combustion-engined vehicle: the focus is on lower energy consumption – regardless of the type of drive system. In the case of electric cars, higher load capacity, optimized rolling resistance and low noise levels are particularly relevant criteria for tire development. The requirements for commercial vehicles are even more rigorous, mainly as a result of the EU’s ‘Clean Vehicles Directive’ and the VECTO tool that seeks to cut CO2 emissions.

Conflicting objectives and the shift in focus

Electric mobility is altering the focus of tire development. The challenge here lies in finding the optimum match between the varying requirements – i.e. the need to achieve high standards of safety, handling and comfort all at once. Electric vehicles are heavier than their ICE counterparts, meaning their tires must be designed to handle greater loads. In order to satisfy all these requirements, both the tire structure and the compounds are undergoing further development. This produces some conflicting objectives that need to be resolved to a high level. The three focal points here are rolling resistance, tire noise and lifespan. New concepts and products from Continental, such as the digital solutions it offers for commercial vehicles, point the way ahead to predictive maintenance and demonstrate the potential of new materials for making vehicle use efficient, safe and sustainable.

Valuable real-world experience: Extreme E, MOIA and Futuricum

Continental is channeling its expertise gained through numerous collaborations and development partnerships – for example with Extreme E, MOIA and Futuricum – directly into the development of next-generation tires. Developers from Continental on both the passenger car and commercial vehicle side have joined forces with manufacturers and customers to work on new concepts and investigate which requirement profiles work best in practice. The ‘Electric Mobility and Tires’ white paper uses eight examples to illustrate the various aspects at the forefront of development in the electric car, truck and bus segments. The white paper offers a comprehensive package of materials to give the reader a sound understanding of the topic and the overall context. The new ‘Electric Mobility and Tires’ white paper from Continental can be accessed here.

Incidentally, the new “Runde Sache” tire podcast from Continental (available in German only) also deals with tires for electric mobility. The episode “Volle Fahrt in Richtung Zukunft” (“Full steam ahead into the future”) features Continental experts Daniel Bäuning and Michael Koch speaking with sports presenter Oliver Forster about trends in tire development and mobility in general. You can find all episodes of the podcast here: www.continental-reifen.de/podcast

Annette Rojas

Business Area Replacement Tires EMEA

Spokesperson Commercial Vehicle Tires

Continental Tires