Vehicles with Continental Thermal Management offer a more efficient ride, they go further and charge faster

- Thermal Management: a future-safe technology for the innovative market – offering benefits for vehicles with or without combustion engine

- Core products include energy-efficient durable pumps, intelligent flow control valves, sensors, plus lines and hoses

- Mass production in China is scheduled to start towards the end of 2019 to meet local demand in a strongly growing electric vehicle market

Regensburg (Germany), Shanghai (China), September 20, 2018. At the Global Future Mobility Conference & Expo 2018 in the Hangzhou International Expo Center from September 20-23, 2018 technology company Continental is unveiling Thermal Management solutions within a personal exchange with leading representatives of the Chinese market. While the main focus is on electric vehicles, drivetrains with and without combustion engine both benefit from high-performance thermal management (TM), which coordinates the generation and flow of heat on an overall level. A vehicle with combustion engine will offer a cleaner and more efficient ride thanks to TM. Electric vehicles will offer considerably more range during very cold or hot ambient temperatures as TM helps to protect the battery charge level – plus it speeds up the charging process.

Continental is already supplying energy-efficient pumps and also sensors of the type required for TM. These are complemented by new Coolant Flow Control Valves (CFCV) that serve to flexibly switch heating and coolant circuits. Finally, the portfolio includes lines and hoses which can provide an integrated sensor function (Smart Rubber). In connection with new control principles the products of the flexible and modular TM construction design make it possible to increase an electric vehicle’s range in the winter season: While the range of a current electric vehicle may drop by up to 40 % at -10 °C when compared to the range at 20…25 °C, the Continental TM can improve the range under the same -10 °C conditions by around 25 %.

„The Continental Thermal Management is based on a flexible and modular set of components, which allow to design economic solutions for different electrified vehicles “, said Klaus Hau, Head of Sensors & Actuators business unit, Continental Powertrain division. „The substantial range increase of electric vehicles and the faster charging are particularly attractive features. Continental’s global presence, innovation and focus on quality in a competitive market place make us an ideal partner for an automotive manufacturer´s thermal management systems.”

More Range for Electric Vehicles

„Thermal Management is a genuinely forward-looking technology as it is not bound to a specific type of drivetrain“, says Peter Biber, Head of Continental China Powertrain Sensors & Actuators (S&A). „TM will make a contribution to vehicle efficiency with both, combustion engine and electric vehicles“. While thermal management will help to minimize the fuel consumption and emissions of a combustion engine as well hybrid vehicles, the focus in a pure electric vehicle is on range. During winter and midsummer – when there is a high demand for heating or cooling – the range of an electrified vehicle is considerably lower because the electric energy for heating or cooling is taken from the Li-Ion battery as well. For instance, at -10 °C up to 30 % of the stored electric energy are needed for heating purposes. Thermal Management serves to facilitate as much heating and cooling as possible without draining the battery. „If I have to recharge less frequently and to a lesser degree this will increase the service life of my battery“, Biber adds.

Ensuring Battery “Wellness” and Faster Charging

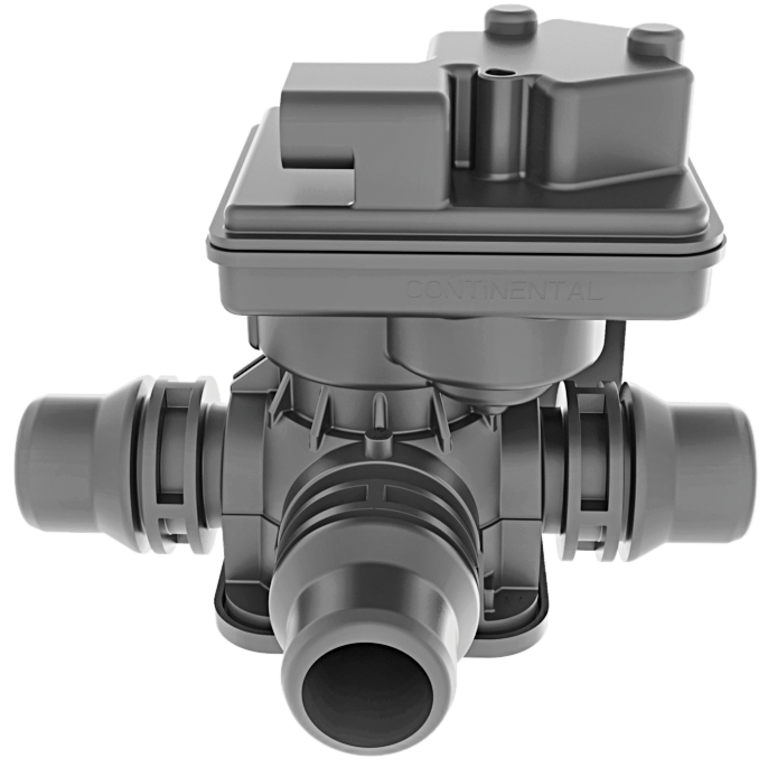

Continental is developing innovative components for new use cases such as battery pre-conditioning. A Li-Ion battery should be in a 25…35 °C temperature span to either receive strong currents (e.g. during fast charging and regenerative braking) or to deliver high currents (during sporty driving). At very low or high temperatures, however, a battery can neither take a lot of recuperated energy nor can it deliver much power. The TM components provide the technical infrastructure to initially heat up the battery and other components of the electric drivetrain and then to switch to cooling at a certain point. During charging, for instance, active cooling of the battery prevents a de-rating of the charge current because the battery temperature is controlled. “This requires flexible switching of coolant circuits and extremely durable, silent and energy-saving pumps and multi-port valves,” Biber explains. „Our new Coolant Flow Control Valves can switch the flow proportionally between two to four coolant circuits. This brings available heat or cold to places where they are needed.”

The Continental Coolant Flow Control Valves (CFCVs) are fully integrated with rotary actuators that provide intelligent positioning of the valve in response to the needs of the vehicle. The actuator uses a compact, brushless motor to provide long lifetime actuation and minimum energy consumption. This unique integrated solution from Continental ensures quality and reliability without sacrificing flexibility. The CFCV’s lightweight design supports customers’ weight reduction efforts, and the small package size opens up new opportunities for placement in the vehicle. “With the Coolant Flow Control Valve product family, Continental offers a full range of solutions for thermal management that increase the efficiency and range of vehicles while improving comfort”, Biber says.

As TM is more complex in an electric vehicle than in a conventional car, the technology company Continental utilizes comprehensive cross-divisional know-how: The modular product portfolio encompasses sensors, innovative actuator modules (BLDC-driven pumps, hydraulics, valves), the required innovative lines and hoses (including sealing solutions; Smart Rubber with integrated sensor function) plus new control concepts for operating conditions during which TM can boost vehicle efficiency.

General press release: Continental Thermal Management Increases Vehicle Efficiency by 25 Percent

Simone Geldhäuser

Head of Media Relations, Spokesperson Finance, Business and Technology

Vitesco Technologies