Continental Produces 48-Volt Drives in Nuremberg

- From the end of 2016, diesel variants of the Renault Scénic and Grand Scénic models will be equipped with Continental's 48-volt hybrid drive.

- Supplier invested €15 million in new production equipment.

- Modular manufacturing concept facilitates delivery to various automotive manufacturers.

- Cost-efficient joining technology through Bavarian research partnerships.

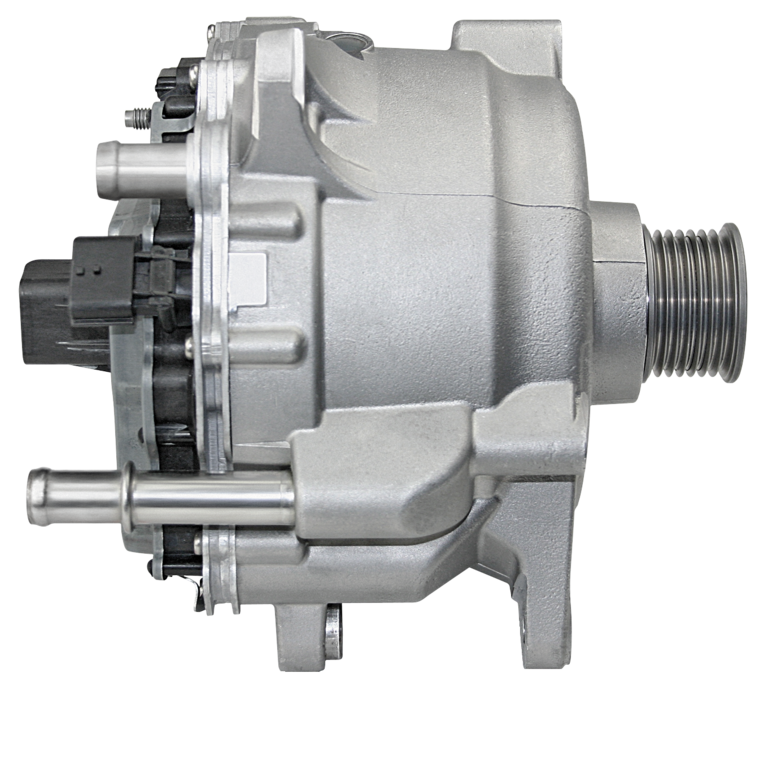

Nuremberg, December 15, 2016. The world’s first hybrid drives that run on 48-volts come from the Continental plant in Nuremberg. Continental is electrifying one diesel variant of both the new Renault Scénic and Grand Scénic models. The system, offered as a "Hybrid Assist" uses a 48-volt hybrid drive in production vehicles for the first time. Just three years after the start of the project, the location developed a modular manufacturing concept that it could use to manufacture efficiently and in line with the cost structures of the volume market. To do so, the supplier invested around €15 million in new production equipment. Using the currently installed equipment, up to 200,000 vehicles can be furnished with 48-volt drives. A modular concept means that products for various automotive manufacturers can be produced with this equipment. The products differ in terms of their size, output or connections – for cooling, for instance. Location Head Rainer Pühl points towards further growth potential: “The manufacturing concept is designed so that completely identical equipment can also be constructed in other regional markets at a later date, for instance in China or the U.S.”

Hybridization with a 48-volt drive results in an especially favorable cost-benefit ratio. Although the continuous electrical output of six kilowatts is relatively low, it allows the system to recover the majority of the kinetic energy that would otherwise be converted into heat during braking. This reduces fuel consumption in the new European driving cycle by up to 13 percent. In real-world use – especially in cities – the savings are even higher thanks to the greater share of driving spent in energy recuperation phases, and can reach up to 21 percent. Rudolf Stark, Head of the Hybrid Electric Vehicle Business Unit, explains: “When industrializing the 48-volt systems, we closely coordinated the development of product and production processes from the start in order to ensure cost-effective production. This is necessary in order to bring large quantities of the technology to market. We expect good market penetration across all vehicle segments, from A to D.”

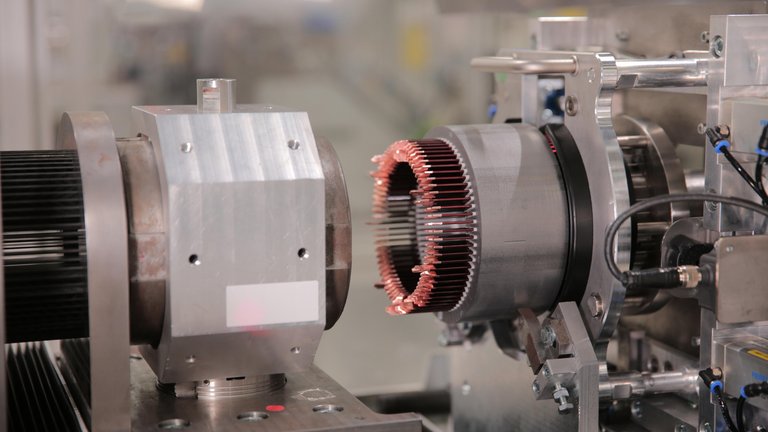

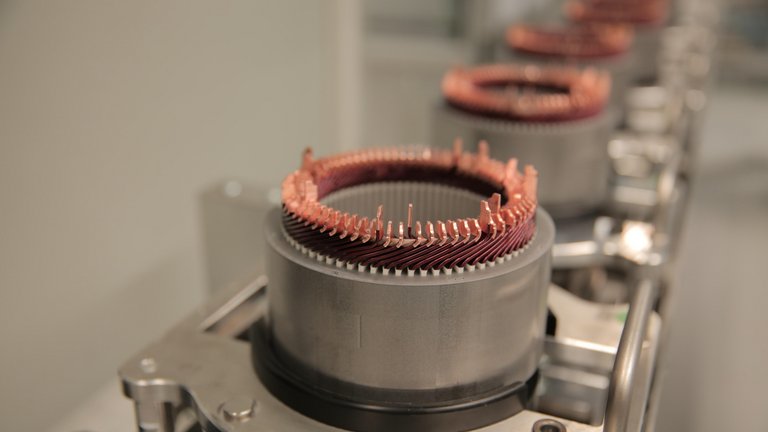

One example of a process innovation is the stator – the stationary portion of the electric motor. Continental does not wind copper wires, as would be typical in traditional electric motor production. Instead, we use more than 100 copper pins that a robot inserts into the substrate in a fully automatic process. Afterward, the individual pins are precisely joined together via laser beam welding. We were able to find a laser beam welding process for copper components that achieves the desired precision through our research partnership with the Bavarian Laser Center in Nuremberg. Continental also developed a new process for joining the two parts of the housing. The 48-volt drive is installed near the underbody instead of a conventional starter and must fulfill especially high requirements for mechanical strength. Therefore, the housing is not only screwed in place; it is firstly joined with an innovative process called “shrinking.” By heating and then cooling or “shrinking” housing components, we can create a very solid joint that guarantees the protection of the electric components inside. In order to achieve a perfect fit, Continental developed a suitable simulation process in collaboration with the Fraunhofer Institute for Integrated Systems and Device Technology (IISB). Bayern innovativ, the Bavarian center for technology transfer, supported Continental in searching for suitable research partners.

The manufacturing segment for the 48-volt drives is divided into a total of three lines. The rectifier is produced on the first line; it serves as an interface between the battery, which works with direct current, and the on-board power supply, which uses alternating current. At the same time, the power electronics activate the electric motor. The stator is manufactured on a second line, and final assembly is completed on a third. The design of the lines was simulated at an early stage of development in order to guarantee the most economical workflows possible. This allowed us to reduce employee walking distances by more than 40 percent through multiple optimization steps.

“With the new 48-volt drive, we are combining decades of intensive experience in semiconductor technology with an entirely new motor concept here at the Nuremberg location. With our modular manufacturing concept, we can facilitate efficient manufacturing that is in line with the cost structures of the volume market,” says Pühl.

The Continental Nuremberg site is a center of excellence of international significance for electromobility, primarily due to the site in the northeast, where the Hybrid Electric Vehicle Business Unit – which is responsible for all key components of the electric drive – both develops and manufactures. Furthermore, Continental's Transmission Business Unit is also headquartered here. The automotive supplier employs around 2,500 people here in the Franconian metropolis.

Simone Geldhäuser

Head of Media Relations, Spokesperson Finance, Business and Technology

Vitesco Technologies