When You Are Really Keen on What You Do

This post is also available in Russian

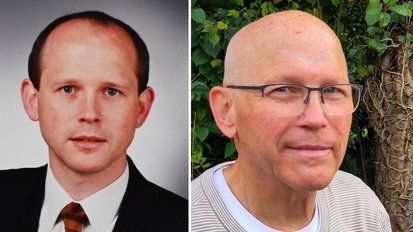

My name is Vadim, I am a graduate of Bauman Moscow State Technical University (Kaluga branch), Industrial Ecology & Chemistry Department, currently working as a Process Engineer at Continental’s plant in Kaluga/Russia. At the same time, I am also really into programming. After my graduation while working for Beeline and Fuyao Glass Rus, I started developing computer programs to automate operating processes. This wealth of knowledge and experience has turned out to be very useful at Continental.

My recent project «Rubber Duck» is a new tool for extrusion. It automates recipe preparation and facilitates data analysis. This software ensures quick and accurate compounding and avoiding any loss at the line. The «Rubber Duck» project was nominated for ContiTireAward 2019, «Trust» category, successfully passed the local level and was forwarded to the regional level.

There are three engineers operating three machines that produce tread, sidewall and inner liner in the Extrusion area. I operate the inner liner machine. Once I was left in charge of the Extrusion area while my colleagues were away. And that was when I faced a problem of making recipes for the machines and tracking their readiness.

In the Extrusion area, we worked with the Excel file that served as a technological process database containing recipes – parameters used by the machines to manufacture the product. A huge number of cells are updated manually: weight, width, article, etc. Some articles are taken out of production while others are newly introduced. The data often got lost, someone failed to enter something into the spreadsheet or made a mistake while entering – the machine won’t start, and everything has to be done again.

I could not even imagine the amount of data that had to be updated manually until I personally faced the problem. And there were loads of compound specifications. For example, there might be up to eight specifications for tread and sidewall production per day, and for each one we need to prepare a recipe.

Entering data in one program, updating and transferring into another program, spreadsheet, their synchronization and analysis – this mechanical work took a lot of time and effort, while requests had to be tackled promptly and in due time. The logical solution was to simplify and automate my own and my colleagues’ work. It took me two weeks to develop a draft solution, and then we started to run the program and add data together. The program is still being improved.

The program was designed to ease our everyday routine and I wanted the name, as well as the tool itself, to be light, kind of joke and associated with the tire industry at the same time. That’s how «Rubber Duck» came to be.

I believe that to do an excellent job you have to be really keen on what you do. Support offered by the team, people’s willingness to discuss problems and find a solution, buddy system – all the things that differentiate Continental from other plants – help a lot. I’m very glad that our team supported the project and the «Rubber Duck» helps to carry out production tasks in the Extrusion area and other departments. This is particularly important now when our life is getting more dynamic and we have to work harder.

This article was written by our employee

Vadim