A Typical Day of a Shift Auditor for Machining in the Quality Department

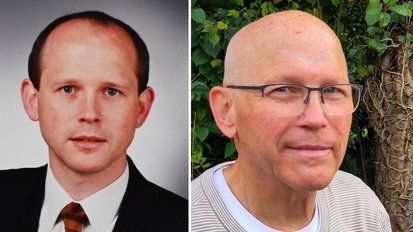

My name is Barbora Kukučková and I work in Zvolen (Slovakia) as a shift auditor for machining in the quality department. I work with Continental since March 2015.

In this article I would like to share a typical day in my work life with you

6 a.m.

My day begins early – but I don’t mind, as I enjoy having the afternoon free for leisure activities. I work in brake caliper machining in Zvolen. My workplace is the coordinate measuring machine (CMM) laboratory, which is where my desk and all of my measuring instruments are to be found. Coordinate measuring machines are devices that measure the geometry of physical objects by detecting points on the object’s surface with a sensor. At the start of my shift, I talk with my colleagues to find out whether there were any problems in the previous shift or if there is anything special that needs to be done.

7.30 a.m.

An important, time-consuming daily task begins: calibration of the Zeiss Prismo coordinate measuring machines and the Zeiss DuraMax for 3D scanning and measurement. I prepare the devices by precisely setting them to their initial value. I carefully measure and inspects the profiles, contours and surface roughness of the machined housings and armatures, and document deviations from the correct values.

11 a.m.

Lunch break. If time allows, I stop by the cafeteria for a portion of chicken and rice or one of the other dishes on offer, followed by a coffee, to set me up for the second part of the day.

12 noon

As a metal cutting expert, I regularly perform internal audits. For these, I prepare documentation on the manufactured products and bring it along to the production lines, where I inspect the processes in the assembly area, electroplating and metal cutting. I closely examine product labels, revisions, measuring instruments and finished products. If something needs to be changed or replaced, I note this information and pass it on to my superior.

1-2 p.m.

‘Quality first’ is my maxim. My colleagues can turn to me at any time if they have questions or problems concerning quality. As I make my rounds of the production areas, I always have my work phone with me. I make detailed notes on any occurrences that are unusual or that deviate from the designated process, and pass these notes on to the colleague who takes over from me at 2 p.m. This ensures that processes continue to run smoothly and that quality stays consistently high.

This article was written by our employee.